Bimota uses advanced carbon fiber techniques to build lightweight, strong, and durable chassis components that boost your motorcycle’s performance. Their methods, like hand lay-up and vacuum infusion, guarantee precise fiber alignment and maximum strength while reducing weight. This results in better handling, quicker acceleration, and improved stability. By strategically designing these parts to balance rigidity and flexibility, Bimota enhances your riding experience. Keep exploring to discover how these innovations deliver exceptional quality and performance.

Key Takeaways

- Bimota employs advanced manufacturing techniques like hand lay-up, vacuum infusion, and autoclave curing for precise, durable carbon fiber chassis components.

- Uses carbon fiber’s high strength-to-weight ratio to create lightweight, strong chassis that improve handling and stability.

- Designs chassis by analyzing load paths and stress points to optimize material placement for performance and weight reduction.

- Carbon fiber chassis contribute to quicker acceleration, better maneuverability, and enhanced cornering responsiveness.

- Extends carbon fiber use beyond chassis to body panels and internal parts, enhancing aerodynamics and overall motorcycle performance.

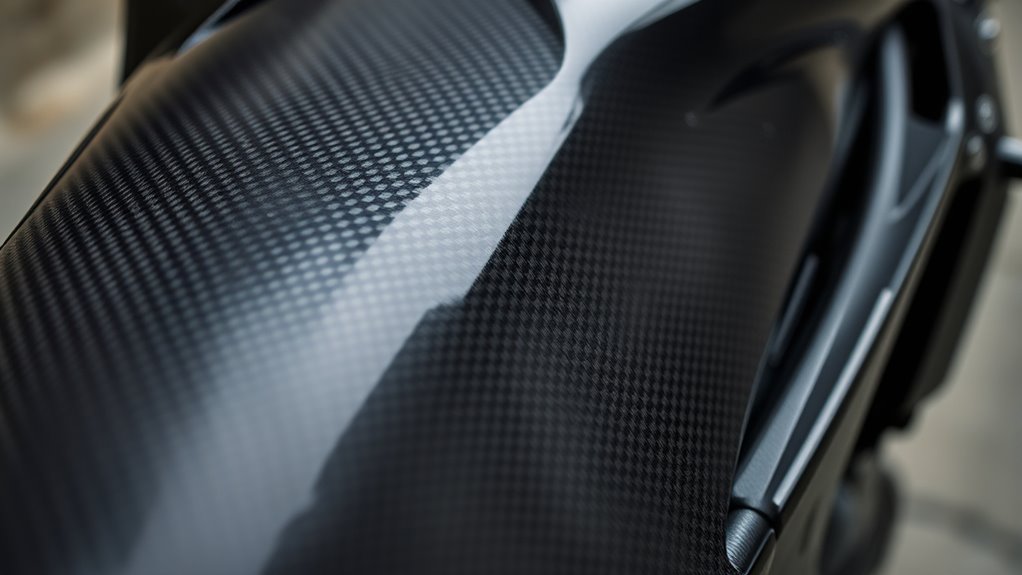

Have you ever wondered how Bimota achieves its reputation for lightweight, high-performance motorcycles? The secret lies largely in their innovative use of carbon fiber manufacturing and their focus on lightweight chassis design. When you ride a Bimota, you’re experiencing the result of meticulous engineering aimed at reducing weight without sacrificing strength or rigidity. Carbon fiber, known for its exceptional strength-to-weight ratio, plays a pivotal role in this process, allowing Bimota to craft chassis components that are both durable and incredibly light.

Bimota’s lightweight, high-performance bikes stem from innovative carbon fiber use and smart chassis design efforts.

In the domain of carbon fiber manufacturing, Bimota takes a precise and controlled approach. They utilize advanced techniques like hand lay-up, vacuum infusion, and autoclave curing to ensure each fiber layer is perfectly aligned and bonded. This meticulous process guarantees that every part of the chassis maintains maximum strength while shedding excess weight. You’ll notice that Bimota’s chassis components are not just lighter but also more resilient, offering better handling and stability on the road or track. This manufacturing precision results in a motorcycle that feels agile and responsive, giving you confidence in every turn and acceleration.

Bimota’s dedication to lightweight chassis design is evident across their entire lineup. They carefully analyze the load paths and stress points to optimize material placement, reducing unnecessary bulk. Every carbon fiber element is designed with purpose, contributing to a frame that’s stiff where it needs to be and flexible enough to absorb shocks. When you hop on a Bimota, you’ll feel how effortlessly the bike responds to your inputs, thanks to this strategic engineering. The reduced weight means less inertia, so acceleration feels quicker, braking is more controlled, and cornering becomes more precise. It’s not just about cutting weight; it’s about enhancing overall performance and rider experience.

Moreover, Bimota’s use of carbon fiber extends beyond just the chassis. They incorporate it into body panels, fairings, and even certain internal components, further reducing weight and improving aerodynamics. This exhaustive application of carbon fiber manufacturing showcases their commitment to innovation and performance. When you ride one of their bikes, you’re experiencing the culmination of years of research and craftsmanship focused on lightweight construction. It’s this blend of advanced materials and thoughtful design that cements Bimota’s reputation. They don’t just build motorcycles; they craft machines that are a tribute to the power of carbon fiber and intelligent engineering.

Frequently Asked Questions

How Does Carbon Fiber Impact Bimota’s Overall Motorcycle Weight?

Using carbon fiber markedly reduces Bimota’s motorcycle weight, making it lighter and more agile. This material enhances the aesthetic appeal with its sleek, modern look, while also increasing manufacturing complexity. You’ll notice improved handling and performance thanks to the weight savings, and the premium feel of carbon fiber adds to the bike’s exclusivity. Overall, it’s an effective way to optimize weight without sacrificing style or strength.

What Specific Chassis Components Are Made From Carbon Fiber?

Your Bimota’s chassis features carbon fiber swingarms and subframes, showcasing stunning aesthetics with the lightweight material. These components demand precise manufacturing challenges, but the result is a chassis so sleek it almost defies gravity. The use of carbon fiber not only enhances visual appeal but also reduces weight markedly, giving you razor-sharp handling and a futuristic look. You’ll notice the difference every time you ride.

How Does Carbon Fiber Affect the Bike’s Handling and Stability?

Carbon fiber enhances your bike’s handling and stability by reducing weight, which boosts aerodynamic efficiency and allows for quicker maneuvering. You’ll notice improved responsiveness and confidence, especially at high speeds or in tight cornering. Plus, the material’s strength maintains rider ergonomics, providing a stable yet agile ride. Overall, carbon fiber makes your bike feel lighter, more balanced, and easier to control, elevating your riding experience markedly.

What Are the Cost Implications of Using Carbon Fiber in Production?

Using carbon fiber increases production costs due to the expensive material and complex manufacturing challenges. You’ll need to conduct a detailed cost analysis to weigh these expenses against the benefits of lighter weight and enhanced performance. The manufacturing challenges involve specialized equipment and skilled labor, which can drive up costs further. Ultimately, the higher price point reflects these added expenses, impacting the overall retail price and potential profit margins.

How Durable Is Bimota’s Carbon Fiber Chassis Under Stress?

Is your curiosity about durability a proof to your keen eye? Bimota’s carbon fiber chassis withstands stress remarkably well, thanks to advanced manufacturing techniques that mitigate issues like carbon fiber fatigue. While manufacturing challenges exist, they’re expertly managed, ensuring the chassis remains resilient under demanding conditions. You can trust that, with proper design and quality control, the chassis provides both strength and longevity, making it a reliable choice for high-performance riding.

Conclusion

You can see that Bimota’s use of carbon fiber truly elevates their chassis, blending lightweight design with incredible strength. It’s clear they’re pushing boundaries to deliver high-performance bikes. Remember, sometimes less is more, and in this case, cutting weight doesn’t mean sacrificing durability. With innovations like these, Bimota proves that strength and agility go hand in hand—showing that the proof is in the pudding. Keep an eye on their progress; they’re just getting started.