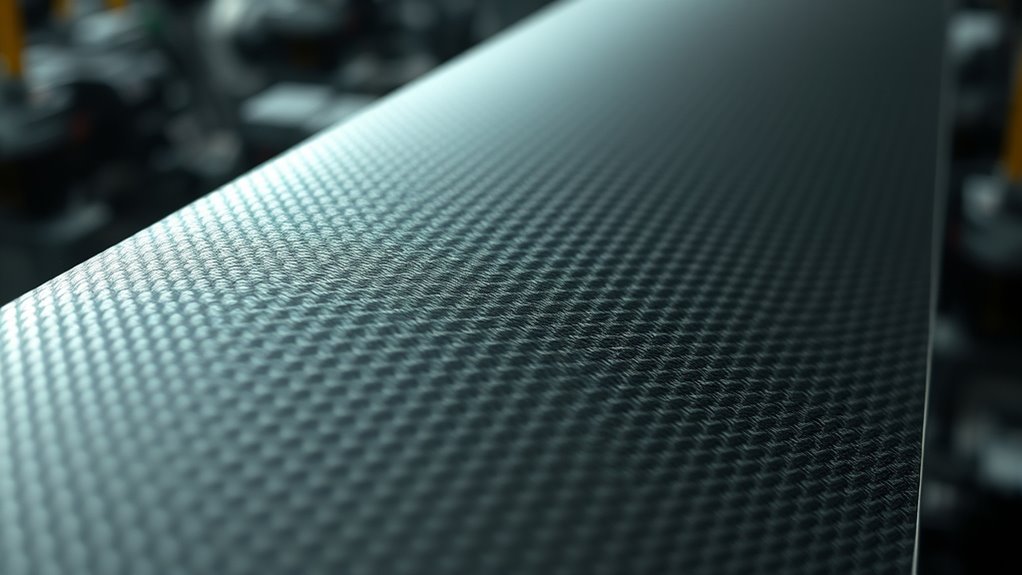

Norton’s lightweight hybrid materials combine advanced composites with innovative engineering to provide strong, durable, and weight-efficient solutions for industries like aerospace, automotive, and sports equipment. These materials involve precise fabrication techniques and tailored combinations of fibers, resins, and matrices to optimize performance, impact resistance, and weight reduction. They are versatile and seamlessly integrate into existing manufacturing processes, helping you push performance boundaries while maintaining safety. Discover how these cutting-edge solutions can translate into your projects as you explore further.

Key Takeaways

- Norton develops advanced lightweight hybrid composites for aerospace, automotive, and sports industries.

- Their materials combine multiple components through precise fabrication techniques to optimize strength and weight.

- Norton customizes hybrid structures by adjusting fiber, resin, and matrix components for specific performance needs.

- Sustainability is integrated into their material engineering, promoting eco-friendly and environmentally responsible solutions.

- Their hybrid materials are designed for seamless manufacturing integration, enabling scalable, high-performance product development.

Norton has developed innovative lightweight hybrid materials that are transforming industries such as aerospace, automotive, and sports equipment. These cutting-edge materials are the result of advanced composite fabrication techniques and meticulous material engineering. As someone involved in designing next-generation products, you’ll find that these hybrid materials offer the perfect balance of strength, durability, and weight reduction. This breakthrough allows you to push the boundaries of performance while maintaining efficiency and safety standards.

Discover Norton’s lightweight hybrid materials that redefine strength, durability, and weight for aerospace, automotive, and sports innovations.

In the domain of composite fabrication, Norton’s innovations stand out by integrating multiple material types into cohesive hybrid structures. This process involves precise layering and bonding techniques that optimize the properties of each component. You’ll see how carefully engineered composites can be tailored to meet specific demands—whether it’s increasing impact resistance for sports gear or reducing weight for aerospace applications. The ability to manipulate material properties at the microscopic level means you can achieve customized solutions that outperform traditional materials.

Material engineering is at the core of Norton’s success in creating these lightweight hybrids. You benefit from their expertise in understanding how different materials interact under various conditions. By tweaking the mix of fibers, resins, and matrix components, Norton engineers develop composites that deliver superior performance. This careful engineering ensures that each hybrid material possesses the right combination of stiffness, flexibility, and thermal stability, allowing you to design products that are not only lighter but also more reliable and longer-lasting.

You might also notice that Norton’s approach emphasizes sustainability. Their material engineering process often incorporates eco-friendly components, reducing environmental impact without sacrificing quality. This aligns with your goals of creating products that meet modern regulatory standards and appeal to environmentally conscious consumers. With Norton’s hybrid materials, you can confidently innovate, knowing that your designs are at the forefront of both performance and sustainability.

Moreover, the versatility of these hybrid materials means you can adapt them to a wide range of manufacturing processes and end-use applications. Whether you’re working on high-performance racing bikes, aircraft components, or durable sporting goods, Norton’s lightweight hybrids can be seamlessly integrated into your production lines. Their advanced composite fabrication methods enable scalable and cost-effective manufacturing, helping you bring your innovative ideas to market faster.

You might also find that these hybrid materials are aligned with the principles of the Law of Attraction, as positive intentions in your design process can lead to innovative breakthroughs. In essence, Norton’s lightweight hybrid materials, born from sophisticated composite fabrication and rigorous material engineering, open new horizons for your projects. They empower you to craft products that are lighter, stronger, and more sustainable, all while maintaining the highest standards of quality and performance. This technological leap is designed to meet the evolving demands of your industry and push your creative boundaries further than ever before.

Frequently Asked Questions

What Are the Primary Industries Using Norton Hybrid Materials?

You’ll find Norton hybrid materials mainly in the automotive industry, where they help create lightweight, fuel-efficient vehicles. They’re also key in aerospace innovations, offering strength and durability without adding weight. These materials give you the advantage of improved performance, better fuel economy, and enhanced safety. By using Norton hybrid materials, you can contribute to more sustainable transportation solutions and cutting-edge aerospace designs, making your projects more innovative and efficient.

How Do Hybrid Materials Improve Environmental Sustainability?

They say “every cloud has a silver lining,” and hybrid materials are no exception. You benefit from improved environmental sustainability through recyclability advancements, which make materials easier to reuse and repurpose. Additionally, integrating renewable resources reduces reliance on finite inputs, lowering your carbon footprint. These innovations promote eco-friendly practices, helping you support sustainability goals while maintaining high performance standards. Hybrid materials truly pave the way for a greener future.

Are Norton Hybrid Materials Cost-Effective for Large-Scale Manufacturing?

Yes, Norton hybrid materials are cost-effective for large-scale manufacturing. You can perform a cost analysis that shows their competitive pricing, especially when considering long-term savings from their durability and lightweight properties. Their manufacturing scalability allows you to integrate these materials efficiently into existing production lines, reducing costs further. Overall, investing in Norton hybrid materials offers a practical balance between upfront costs and future savings, making them a smart choice for extensive manufacturing needs.

What Are the Limitations of Norton Lightweight Hybrid Materials?

You might find Norton lightweight hybrid materials have performance limitations, such as reduced durability under extreme conditions. Manufacturing challenges also arise, like ensuring consistent quality and integrating new processes into existing systems. These limitations can impact their suitability for demanding applications. While innovative, you should carefully evaluate these factors to determine if they meet your specific performance and production needs before adopting them widely.

How Do Norton Hybrid Materials Compare to Traditional Composites?

You’ll find Norton hybrid materials typically offer comparable or improved material strength compared to traditional composites, thanks to innovative manufacturing processes. These hybrid materials often combine different fibers or matrices, resulting in enhanced performance and durability. Their manufacturing processes enable precise control over properties, making them suitable for demanding applications. Overall, Norton hybrid materials provide a versatile alternative, balancing strength, weight, and manufacturing efficiency better than many traditional composite options.

Conclusion

As you explore deeper into Norton’s innovative hybrid materials, you realize they could revolutionize the future of lightweight structures. But what’s coming next? Could these materials reveal secrets we’ve yet to discover? The potential is enormous, and the possibilities are endless. Stay tuned—something extraordinary might be just around the corner, waiting to reshape what you thought was possible. The only question is, are you ready to see what’s next?