Engine oil analysis helps you spot early signs of engine wear and contamination before they cause breakdowns. By collecting small oil samples, you can check for metal particles, dirt, fuel, and additives, all of which reveal engine health. Monitoring these signs allows you to address potential problems early, saving money and extending your engine’s life. Keep exploring to discover how to use oil analysis effectively and stay ahead of costly repairs.

Key Takeaways

- Regular oil analysis detects metal particles indicating early engine wear before performance declines.

- Monitoring contaminant levels reveals dirt or water ingress that can cause damage and reduce efficiency.

- Tracking additive depletion helps ensure proper lubrication and prevents premature component failure.

- Trend analysis of oil reports identifies gradual wear patterns, enabling proactive maintenance.

- Early detection of issues through oil testing minimizes costly repairs and prolongs engine lifespan.

Understanding the Basics of Oil Analysis

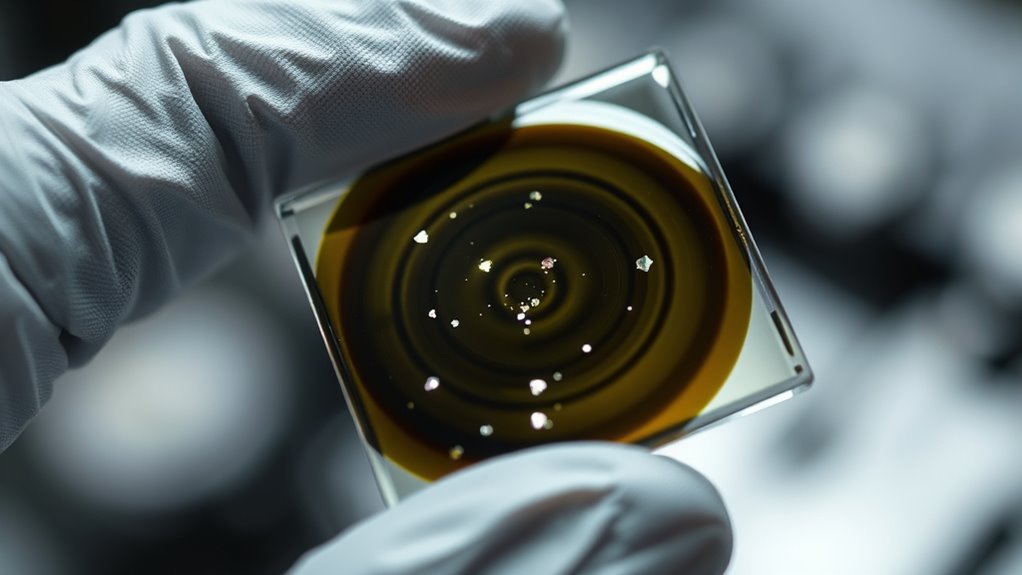

Understanding the basics of oil analysis is essential for maintaining engine health and preventing costly repairs. When you analyze your engine oil, you check for signs of wear, contamination, and chemical changes. This process involves collecting a small oil sample and examining it for metal particles, dirt, fuel, and other contaminants. These indicators reveal how well your engine components are functioning and whether parts are wearing prematurely. Regular sampling helps you catch issues early before they cause significant damage. You don’t need to be an expert to understand the importance—just knowing that oil analysis provides a snapshot of your engine’s internal condition empowers you to make informed maintenance decisions. Engine tuning techniques can help optimize engine performance based on these insights. This proactive approach keeps your engine running smoothly and extends its lifespan.

What Does Oil Composition Reveal?

Analyzing the composition of your engine oil reveals a wealth of information about your engine’s current condition. It shows whether your oil is still effective at lubricating and protecting engine parts or if it’s breaking down. You can identify if contaminants like dirt, water, or fuel have entered the oil, which can cause damage over time. The levels of additives, such as detergents and anti-wear agents, tell you if the oil is still performing its job or needs replacement. Changes in viscosity can indicate overheating or excessive wear. Additionally, incorporating automated data analysis can help interpret complex oil analysis results more accurately. By understanding these details, you gain insight into potential issues before they escalate, enabling timely maintenance. This proactive approach helps keep your engine running smoothly and extends its lifespan.

Detecting Wear Particles and Contaminants

Detecting wear particles and contaminants in your engine oil is essential for identifying early signs of engine damage. When you analyze your oil, look for small metal shavings, dirt, or debris. Metal particles often indicate internal components are wearing down, which can lead to bigger problems if unnoticed. Contaminants like dust or water can cause corrosion, reduce lubrication, and accelerate wear. Using tools like magnetic filters or laboratory testing helps you spot these particles early. If you find an increase in metal fragments or foreign debris, it’s a sign you should investigate further. Regular monitoring of your oil’s condition helps you catch issues before they become severe. Catching these signs early allows you to schedule maintenance before minor issues turn into costly repairs. Regularly monitoring your oil’s condition keeps your engine running smoothly and extends its lifespan.

The Benefits of Regular Oil Testing

Regular oil testing offers a proactive way to maintain your engine’s health, catching potential issues before they become costly problems. It helps you identify early signs of wear, contamination, and oil degradation, so you can address them promptly. This not only extends your engine’s lifespan but also improves performance and fuel efficiency. By staying ahead of potential failures, you avoid unexpected breakdowns and costly repairs. Regular testing also provides peace of mind, ensuring your engine runs smoothly. Here’s a quick overview:

| Benefit | Explanation |

|---|---|

| Early problem detection | Spots issues before they cause major damage |

| Cost savings | Prevents expensive repairs and replacements |

| Extended engine life | Keeps engine components in good condition |

| Improved performance | Maintains excellent lubrication and efficiency |

| Confidence in vehicle health | Regular tests ensure your engine stays reliable |

Additionally, understanding wear patterns can help tailor maintenance schedules and improve overall engine longevity.

Interpreting Oil Analysis Reports

Interpreting oil analysis reports is essential for understanding your engine’s condition and making informed maintenance decisions. When reviewing the report, focus on key indicators such as wear metals, contaminants, and additive levels. Elevated wear metals like iron or copper signal internal engine wear, which could indicate parts are breaking down. High levels of dirt or water suggest contamination, risking damage if not addressed. Pay attention to additive levels—if they’re low, your oil may no longer provide proper lubrication. Look for trends over multiple reports; rising wear metals often point to developing issues. By accurately interpreting these signs, you can identify potential problems early, schedule timely maintenance, and prevent costly repairs down the line. Proper understanding of the report empowers you to keep your engine running smoothly.

How Oil Analysis Prevents Costly Repairs

Oil analysis helps you catch engine issues early before they turn into expensive repairs. By regularly testing your oil, you can detect contaminants, metal wear, and fluid degradation before symptoms become serious. This proactive approach allows you to schedule maintenance at the right time, preventing breakdowns and reducing downtime. For example, identifying metal particles signals internal wear, so you can address problems before components fail. Monitoring oil condition helps you avoid over- or under-maintaining, which can both be costly. Catching issues early means you replace worn parts sooner, saving money on extensive repairs or engine replacements later. Ultimately, oil analysis acts as an early warning system, keeping your engine running smoothly and saving you from unexpected, costly repairs down the road. It also helps maintain optimal engine air quality, ensuring that your engine operates efficiently and prolongs its lifespan.

Implementing an Effective Oil Monitoring Routine

To effectively monitor your engine’s health, establishing a consistent oil testing routine is essential. You should follow a clear plan to catch early signs of wear and prevent breakdowns. First, decide on a testing frequency—most experts recommend every 3,000 to 5,000 miles or with each oil change. Second, keep detailed records of test results, noting any changes in wear metals or contaminants. Third, interpret your data carefully; look for trends such as increasing iron or aluminum levels, which signal potential issues. Regular testing allows you to identify problems early and plan maintenance accordingly. Additionally, understanding sound vibrations can help you appreciate how external factors might influence engine performance. By sticking to this routine, you’ll maintain ideal engine performance and extend its lifespan, saving both time and money in the long run.

Frequently Asked Questions

How Often Should Oil Analysis Be Performed for Optimal Engine Health?

You might wonder how often to perform oil analysis for your engine’s health. Typically, it’s recommended to do it every 3,000 to 5,000 miles or during regular maintenance intervals. If your vehicle operates under heavy loads or extreme conditions, consider more frequent testing. Regular analysis helps you catch wear and contaminants early, preventing potential engine damage and ensuring ideal performance over time.

Can Oil Analysis Predict Engine Failure Before Symptoms Appear?

Oil analysis can indeed predict engine failure before symptoms show. By regularly testing your oil, you detect early signs of wear, contamination, or metal particles that indicate potential issues. This proactive approach helps you catch problems early, allowing timely maintenance and preventing costly breakdowns. So, if you rely on oil analysis, you’re better equipped to maintain engine health and avoid unexpected failures.

What Are the Limitations of Oil Analysis in Diagnosing Engine Issues?

While oil analysis helps detect early signs of wear and contamination, it has limitations. You can’t rely solely on it for diagnosing all engine issues because some problems, like internal cracks or sensor failures, won’t show up in oil samples. Additionally, sampling errors or improper testing can lead to false positives or negatives. So, use oil analysis as part of a thorough maintenance plan, not the only diagnostic tool.

How Does Oil Analysis Differ Across Various Vehicle Types or Industries?

Your curiosity about how oil analysis varies across vehicle types or industries is spot-on. Different engines and machinery have unique demands, so analysis methods adapt accordingly. For example, heavy trucks may need more frequent testing due to intense use, while industrial equipment might require specialized additives. You’ll find that tailoring oil analysis helps you catch potential issues early, saving you from catastrophic failures—like avoiding a disaster of epic proportions.

Are There Specific Indicators in Oil Analysis That Signal Imminent Engine Damage?

You should look for signs like increased metal particles, high levels of contaminants, or abnormal viscosity in your oil analysis, as these indicate imminent engine damage. Elevated wear metals suggest internal component deterioration, while contaminants may point to sealing issues. If you notice these indicators, it’s a warning to perform maintenance or repairs promptly to prevent serious engine failure. Regular oil analysis helps you catch problems early and keep your engine running smoothly.

Conclusion

By regularly testing your engine oil, you catch wear and contaminants early, keeping your engine running smoothly. Think of it as tending a garden—you’ll spot weeds before they take over. Staying proactive with oil analysis saves you money and headaches down the road. Remember, an ounce of prevention is worth a pound of cure. Keep an eye on your oil, and your engine will thank you for it, running strong mile after mile.