To prevent frame cracks during high-speed jumps, guarantee your bike is made from durable materials like reinforced aluminum or carbon fiber, and properly maintained with regular inspections for signs of fatigue or corrosion. Use protective coatings and reinforce high-stress areas, and follow correct jumping techniques to absorb impact smoothly. Managing weight distribution and avoiding overloads also helps. Keep these practices in mind, and you’ll discover more ways to safeguard your frame with continued guidance.

Key Takeaways

- Reinforce high-stress areas like the head tube and chain stays with gussets or thicker tubing.

- Use impact-resistant materials such as carbon fiber or reinforced aluminum alloys for better durability.

- Ensure proper jump technique with controlled speed, smooth takeoffs, and gentle landings to minimize frame stress.

- Regularly inspect and maintain the frame, checking for cracks, rust, or damages, especially after high-impact jumps.

- Apply protective coatings like anodizing or sealants to prevent corrosion and material degradation over time.

Understanding the Causes of Frame Cracks During High-Speed Jumps

When you perform high-speed jumps, your bike’s frame endures intense stress and rapid movements that can lead to cracks. The repeated impact from landing causes metal fatigue, weakening the frame over time. Sharp landings or miscalculations increase stress concentrations at specific points, especially around welds or joints. Fatigue cracks often start small but can grow quickly if ignored. Overloading your bike beyond its recommended capacity adds extra pressure, pushing materials past their limits. Vibrations from rough terrain also contribute, causing microscopic fractures that accumulate. Understanding these causes helps you recognize the importance of proper technique and maintaining your bike. By minimizing undue stress and avoiding aggressive landings, you reduce the risk of developing cracks that compromise your bike’s integrity.

Material Selection for Enhanced Durability

Choosing the right materials is key to preventing frame cracks. You should focus on high-impact resistant options that can withstand sudden forces and stresses. Flexible, stress-absorbing components also help distribute loads and reduce the risk of damage over time. Incorporating pressure relief features in the design can further enhance durability by minimizing strain during high-speed jumps.

High-Impact Resistant Materials

Have you considered how the right high-impact resistant materials can considerably improve the durability of your frames? Using materials like carbon fiber or reinforced aluminum alloys can absorb shocks better and prevent cracks caused by high-speed jumps. These materials are lightweight yet incredibly strong, reducing stress on the frame during impact. They also resist fatigue and deformation over time, ensuring your frame maintains integrity after repeated jumps. When selecting materials, look for those with high tensile strength and impact toughness. Properly chosen high-impact resistant materials can extend your frame’s lifespan, minimize repairs, and boost safety. Additionally, choosing materials compatible with headphone components can help prevent damage from vibrations and impacts, further enhancing durability. Investing in the right materials means your frame can withstand demanding conditions while maintaining excellent performance, giving you confidence and peace of mind during every jump.

Flexible, Stress-Absorbing Components

Building on the importance of impact-resistant materials, incorporating flexible, stress-absorbing components into your frame design can substantially enhance durability. These components help dissipate energy from high-speed jumps, reducing stress concentrations that cause cracks. Materials like rubber, polyurethane, or flexible composites can absorb shocks and allow slight deformations without damage. Incorporating precious metals known for durability can further improve the resilience of critical parts. Integrating these elements at critical points—such as joints, welds, or load-bearing areas—ensures your frame can flex under stress rather than crack. Proper selection is key; choose materials that balance flexibility with strength. By doing so, you maintain structural integrity while allowing for movement that prevents fractures. This approach not only extends your frame’s lifespan but also improves overall performance during extreme jumps, making it a critical aspect of durable frame design.

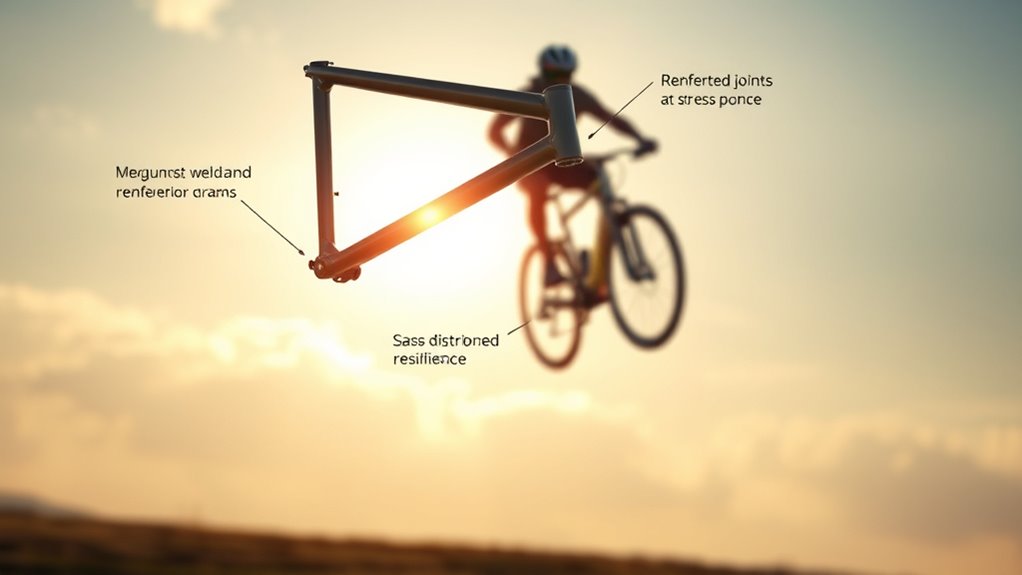

Proper Frame Design and Stress Distribution

To prevent frame cracks, designing the frame to distribute stresses evenly is essential. Proper frame geometry and material choices help spread loads during high-speed jumps, reducing stress concentrations. You should use reinforced joints and smooth welds to prevent weak points. Additionally, optimizing tube thickness and angles ensures better load transfer. Consider the following stress distribution approach:

| Frame Part | Stress Handling Strategy |

|---|---|

| Head Tube | Reinforced for impact absorption |

| Down Tube | Thickened to handle compression forces |

| Seat Stays | Flexible shape to absorb shocks |

| Chain Stays | Reinforced for lateral stresses |

| Top Tube | Smooth curves for even stress flow |

This balanced design minimizes crack risks and enhances durability during high-speed jumps. Maintaining proper load transfer techniques is crucial for long-term frame integrity.

Regular Inspection and Maintenance Practices

Regular inspection and maintenance are essential for preventing frame cracks and ensuring your bicycle’s longevity. Regularly check your bike for signs of wear or damage, especially after high-impact jumps. Look for cracks, dents, or paint chips that could indicate stress points. Keep your frame clean and free of dirt, which can hide cracks or corrosion. Tighten bolts and fasteners regularly to avoid unnecessary stress on joints. Additionally, inspecting self-watering planters can provide insights into structural integrity and moisture management that may be relevant for understanding material stress and failure.

Optimal Jumping Techniques to Reduce Stress

Mastering ideal jumping techniques is essential for minimizing stress on your bike’s frame. When you prepare to jump, keep your body centered and relaxed to absorb impacts evenly. Approach the jump with a steady speed, avoiding sudden acceleration or deceleration that can increase stress. As you lift off, maintain a smooth, controlled motion, avoiding abrupt or jerky movements that transfer excessive force to the frame. Focus on timing your takeoff and landing to distribute impact forces across the bike evenly, preventing concentrated stress points. Use your legs as shock absorbers and keep your arms slightly bent to absorb vibrations. Incorporating tuning options like suspension upgrades can further improve your bike’s ability to handle impacts during high-speed jumps. By adopting these techniques, you reduce the risk of cracks caused by high‑speed jumps, preserving your bike’s integrity and ensuring safer rides.

Implementing Reinforcements for Critical Areas

Implementing reinforcements in critical areas of your bike’s frame can substantially reduce the risk of cracks caused by repeated stress. Focus on strengthening high-stress zones to withstand high-speed jumps and landings. Reinforcements can include adding material patches or using specialized alloys in vulnerable spots. You might also consider integrating gussets or thicker tubing at key junctions to improve durability. These targeted enhancements distribute forces more evenly, preventing stress concentration that leads to cracks.

Strengthen high-stress areas with patches, gussets, or thicker tubing to prevent cracks from stress.

- Use carbon fiber or titanium reinforcements in load-bearing areas

- Reinforce weld joints with additional welding or bonding

- Apply protective coatings or wraps to absorb impact and reduce fatigue

Environmental Factors Affecting Frame Integrity

Environmental factors such as temperature fluctuations, humidity, and exposure to moisture can substantially impact your bike’s frame integrity. Extreme temperatures cause materials to expand or contract, weakening welds and joints over time. High humidity and moisture promote corrosion, especially if protective coatings wear off. This deterioration reduces the frame’s strength, risking cracks during high-speed jumps. To minimize these effects, store your bike in a dry, climate-controlled environment and regularly inspect for rust or corrosion. Proper maintenance, like cleaning and applying anti-corrosion treatments, extends your frame’s lifespan. Additionally, understanding paint sprayer maintenance can help protect your bike’s finish from environmental damage. Here’s a quick reference:

| Factor | Effect |

|---|---|

| Temperature | Material expansion/contraction, stress points |

| Humidity/Moisture | Corrosion weakening the frame |

| Sun Exposure | UV damage to coatings, material degradation |

| Storage Conditions | Prevents rust, maintains structural integrity |

Managing Load Limits and Weight Distribution

Are you ensuring your bike’s load and weight are properly balanced? Proper weight distribution reduces stress on your frame during high-speed jumps, preventing cracks. To manage load limits effectively:

- Keep heavier items low and centered on the frame to maintain stability.

- Avoid overloading beyond your bike’s specified weight capacity.

- Distribute weight evenly between the front and rear to prevent undue stress on any single area.

- Incorporating sound vibrations in your maintenance routine may also help enhance your bike’s overall health and resilience.

Using Protective Coatings and Treatments

Applying protective coatings and treatments to your bike frame adds an extra layer of defense against cracks caused by stress and environmental factors. These coatings, like epoxy or specialized sealants, help reinforce the material and reduce the impact of moisture, dirt, and chemicals that can weaken the frame over time. Treatments such as anodizing or ceramic coatings create a durable barrier, preventing corrosion and surface damage that could lead to crack initiation. Regularly applying these protections ensures your frame maintains its integrity after high-speed jumps and rough landings. Be sure to follow manufacturer instructions for application to maximize effectiveness. Using protective coatings is a proactive step that extends your bike’s lifespan and helps prevent costly repairs or replacements caused by frame cracks.

Training and Education for Jumpers and Operators

Proper training and education are essential for jumpers and operators to prevent frame cracks and guarantee safety. When you understand the correct procedures, you reduce the risk of overloading or improper handling that can cause stress on the frame. Focus on these key areas:

- Recognizing signs of wear and fatigue to address issues early

- Following proper jump techniques to minimize unnecessary strain

- Regularly inspecting equipment and adhering to maintenance schedules

Frequently Asked Questions

How Do Temperature Changes Influence Frame Crack Development During Jumps?

Temperature changes impact frame crack development because they cause materials to expand and contract. When you perform high-speed jumps, rapid temperature shifts can create stress within the frame, making it more prone to cracks. You should monitor the temperature and allow the frame to adapt gradually. Using materials with better thermal resistance can also help minimize crack formation, ensuring your frame stays stronger during intense jumps.

What Role Does Fatigue Play in the Lifespan of High-Speed Jump Frames?

Imagine you’re repeatedly jumping at high speeds; over time, fatigue can weaken your frame. Fatigue causes microscopic cracks to form and expand, reducing its overall lifespan. For example, a cyclist noticed her bike frame developed small cracks after several months of intense riding. Similarly, high-speed jump frames endure cyclic stress, and without proper maintenance or material choice, fatigue accelerates failure, ultimately shortening the frame’s durability and risking catastrophic breakage.

Are There Industry Standards for Maximum Stress Thresholds in Frame Design?

You should know that industry standards for maximum stress thresholds guide how frames are designed to guarantee safety and durability. These standards set limits on the amount of stress a frame can handle without failure, helping you prevent cracks and structural issues. By adhering to these guidelines, you can optimize your frame design for high-speed jumps, reducing risk and extending the lifespan of your equipment effectively and reliably.

How Can Real-Time Monitoring Systems Detect Early Signs of Frame Stress?

You can use real-time monitoring systems to detect early signs of frame stress by installing sensors that track strain, vibration, and temperature changes. These sensors send continuous data to a central system, which analyzes patterns for anomalies indicating stress buildup. By catching issues early, you can take immediate action, reducing the risk of cracks or failures during high-speed jumps. Regular calibration and data review help guarantee accuracy and reliability.

What Are the Latest Innovations in Materials for Anti-Crack Frame Construction?

You should explore the latest innovations in materials for anti-crack frame construction, such as advanced composites like carbon fiber-reinforced polymers and ultra-high-performance concrete. These materials offer exceptional strength, flexibility, and durability, reducing crack formation under stress. Incorporating nanomaterials and self-healing composites also enhances resilience. By adopting these cutting-edge options, you can markedly improve your frame’s ability to withstand high-speed jumps and other demanding forces.

Conclusion

To keep your frame from cracking during high-speed jumps, stay vigilant with regular inspections, choose durable materials, and master proper techniques. Don’t forget to respect load limits and environmental conditions—think of it as your own personal “hack” to longevity. With diligent care and a bit of foresight, you’ll avoid costly repairs and keep your jumps smooth as silk. Remember, even in this fast-paced world, a little patience and maintenance go a long way!