Norton’s braking system design focuses on delivering reliable, high-performance stopping power while ensuring rider safety and confidence. You’ll find advanced materials like carbon-ceramic composites and specialized aluminum alloys that enhance heat resistance, durability, and smooth operation. Rigorous testing under real-world conditions guarantees consistent performance, quick response, and reduced vibrations. If you want to discover how Norton synchronizes advanced engineering to maximize braking efficiency and rider control, there’s more to explore below.

Key Takeaways

- Norton’s braking system prioritizes reliable stopping power, rider safety, and performance through advanced material selection and design integration.

- Utilizes high-performance composites, specialized alloys, and heat-resistant metals for optimal friction, durability, and thermal stability.

- Undergoes rigorous testing in real-world conditions to ensure consistent, responsive, and noise-free braking performance.

- Engineered for seamless interaction with motorcycle design, focusing on quick response, precise modulation, and vibration reduction.

- Aims to deliver durable, safe, and high-performance braking solutions that support rider confidence and uphold Norton’s engineering standards.

Norton’s braking system design focuses on delivering reliable and efficient stopping power to guarantee rider safety and performance. When you ride a Norton, you want to trust that your brakes will respond instantly and smoothly, no matter the situation. That’s why one of the core aspects of their design revolves around maximizing braking efficiency. Achieving this means carefully balancing force application, heat dissipation, and pedal or lever feel. The goal is to provide you with consistent, predictable braking performance, so you can handle sudden stops or controlled decelerations with confidence. To do this effectively, Norton places significant emphasis on material selection, which directly impacts braking efficiency. The choice of brake components isn’t arbitrary; it’s a strategic decision aimed at optimizing friction, durability, and heat resistance.

Norton’s brakes ensure reliable, smooth stopping with optimized materials for safety and durability.

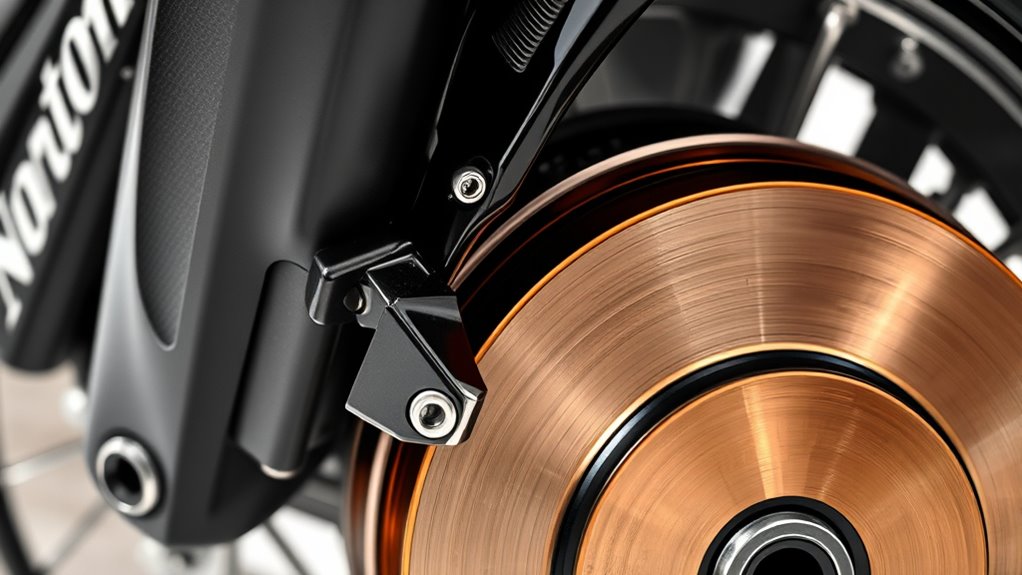

In Norton’s design, you’ll find that high-quality materials like advanced composites, special alloys, and treated metals are used for brake discs, calipers, and pads. These materials are selected because they offer superior thermal stability and wear resistance, ensuring your brakes won’t fade under heavy use. For example, Norton often incorporates carbon-ceramic composites or specialized aluminum alloys that can withstand high temperatures without losing their stopping power. This material selection not only enhances braking efficiency but also extends the lifespan of the components, reducing maintenance needs and ensuring your bike remains reliable over time. The design process involves rigorous testing of these materials under real-world conditions, simulating various riding scenarios to confirm their performance and longevity. Additionally, understanding and implementing proper automotive repair basics can help in maintaining and troubleshooting these complex systems over their lifecycle.

You’ll notice that Norton’s braking components are engineered to work harmoniously with the overall motorcycle design, ensuring that brake response is quick and modulation is precise. They pay close attention to how different materials interact, aiming to minimize vibrations and noise, which can compromise braking feel. The system’s architecture also considers weight, as lighter materials contribute to better handling and acceleration, without sacrificing safety. When you press the brake lever, you want a firm, predictable response—Norton’s material choices and design principles ensure just that. They aim to deliver a braking experience that’s both powerful and controllable, giving you the confidence to ride at higher speeds or navigate complex terrains.

Ultimately, Norton’s focus on material selection and engineering excellence results in a braking system that’s efficient, durable, and safe. You can rely on it to perform consistently, whether you’re cruising on open roads or tackling challenging conditions. Their commitment to refining these components highlights their dedication to rider safety and performance, making Norton a trusted name among motorcycle enthusiasts.

Frequently Asked Questions

What Materials Are Used in Norton’s Braking System Components?

You’ll find that Norton’s braking system components use high-quality materials like cast iron and aluminum for the brake drums and calipers, guaranteeing durability and heat resistance. The brake pads are typically made from semi-metallic or organic compounds, providing reliable stopping power. The brake lines are often reinforced rubber or braided stainless steel for strength and flexibility. This combination of braking system materials ensures peak performance and longevity of Norton brake component composition.

How Does Temperature Affect Braking Performance?

While temperature might seem like a minor factor, it greatly impacts braking performance. As brakes heat up, thermal expansion can cause components to expand, reducing contact efficiency. Excess heat also hampers heat dissipation, leading to brake fade and decreased stopping power. You’ll notice that maintaining ideal temperature levels ensures consistent braking, preventing overheating and keeping your braking system responsive and safe during intense rides or prolonged use.

What Maintenance Is Required for Optimal Efficiency?

You need to regularly check your braking fluid level and top it off if needed to ensure smooth operation. Inspect your brake pads frequently for wear and replace them when they’re thin to maintain peak braking performance. Keep the braking system clean and free of debris, and guarantee all bolts and components are secure. Proper maintenance of these parts helps prevent overheating and guarantees reliable stopping power when you need it most.

Are There Any Common Issues With Norton’s Braking System?

Like a vintage radio, Norton’s braking system can develop issues over time. Common problems include reduced braking system durability and sensor calibration errors, leading to decreased stopping power. You might notice uneven braking or delayed responses. Regular maintenance helps prevent these issues, ensuring your brakes stay responsive. Stay vigilant, check the sensors, and replace worn components promptly to maintain safety and reliability on the road.

How Does the Braking System Integrate With Overall Motorcycle Safety Features?

Your braking system integrates seamlessly with overall motorcycle safety by working in harmony with other safety features like ABS and stability controls. This braking system integration enhances your control during sudden stops or tricky conditions, reducing the risk of accidents. By ensuring reliable and responsive braking, it plays a vital role in maintaining your safety on the road, giving you confidence and protection in various riding scenarios.

Conclusion

Think of Norton’s braking system as the steady hand guiding you through a storm. Just like a reliable brake keeps you safe on a slippery road, this design guarantees control and safety at high speeds. Remember the rider who trusted his brakes during a sharp turn and came out unscathed? That’s the power of a well-designed system—trust it, and you’ll navigate life’s twists with confidence and security.