To inspect the valvetrain on high-revving four-stroke engines, you need to routinely check for signs of wear like unusual noises, uneven valve clearance, or visual damage to components such as rocker arms and valves. Use precise tools like feeler gauges, dial indicators, and flashlights to examine valve clearances, spring tension, and cam timing. Address any issues early to prevent engine damage, and if you continue exploring, you’ll discover detailed inspection steps and maintenance tips.

Key Takeaways

- Regularly inspect rocker arms, valves, and cam lobes for signs of wear, pitting, or scoring.

- Measure valve clearance and spring tension accurately using feeler gauges and dial indicators.

- Check timing marks and sprockets for proper alignment and wear to ensure correct camshaft timing.

- Look for oil leaks, buildup, or corrosion that could indicate underlying valvetrain issues.

- Use appropriate tools like borescopes and mirrors for detailed visual inspections of hard-to-reach components.

Understanding the Importance of Valvetrain Care in High-Speed Engines

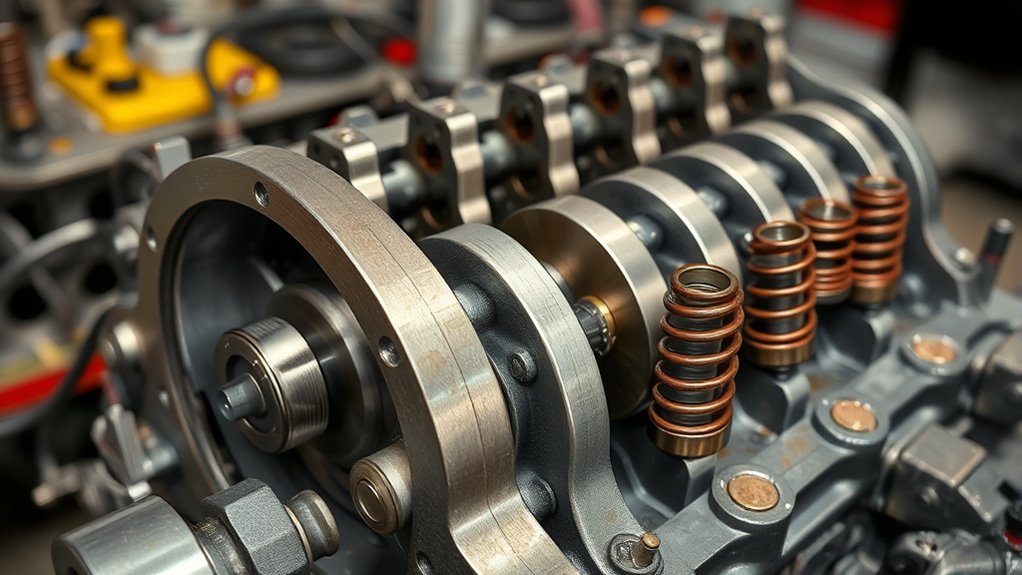

Understanding the importance of valvetrain care in high-speed engines is essential because the valvetrain plays a critical role in engine performance and reliability. When you’re operating at high RPMs, even minor issues in the valvetrain can cause significant problems, such as power loss, misfires, or catastrophic engine failure. Proper maintenance ensures that components like valves, springs, and rocker arms function smoothly and efficiently. Color accuracy impacts overall image quality and is especially important when assessing the condition of engine components visually during inspections. Neglecting valvetrain care can lead to increased wear, loss of compression, and uneven valve timing, which compromise engine output and longevity. Regular inspections and adjustments help you catch early signs of wear, preventing costly repairs and keeping your engine running at peak performance. In high-revving engines, proactive valvetrain care is key to reliability and maximum power.

Common Signs of Valvetrain Wear and Damage

Recognizing the early signs of valvetrain wear and damage is essential for maintaining engine health, especially in high-performance setups. Ignoring these signs can lead to serious engine issues and costly repairs. You should watch for unusual noises such as ticking or tapping sounds, which indicate worn lifters or valves. A drop in engine performance, like misfires or rough idling, also signals potential problems. Additionally, look for increased exhaust emissions or oil consumption, as these can point to worn valve seals or guides. Ultimately, inspect for visible signs of wear, such as pitting on rocker arms or excessive valve clearance. Staying alert to these symptoms helps you catch problems early and keeps your engine running smoothly at high RPMs.

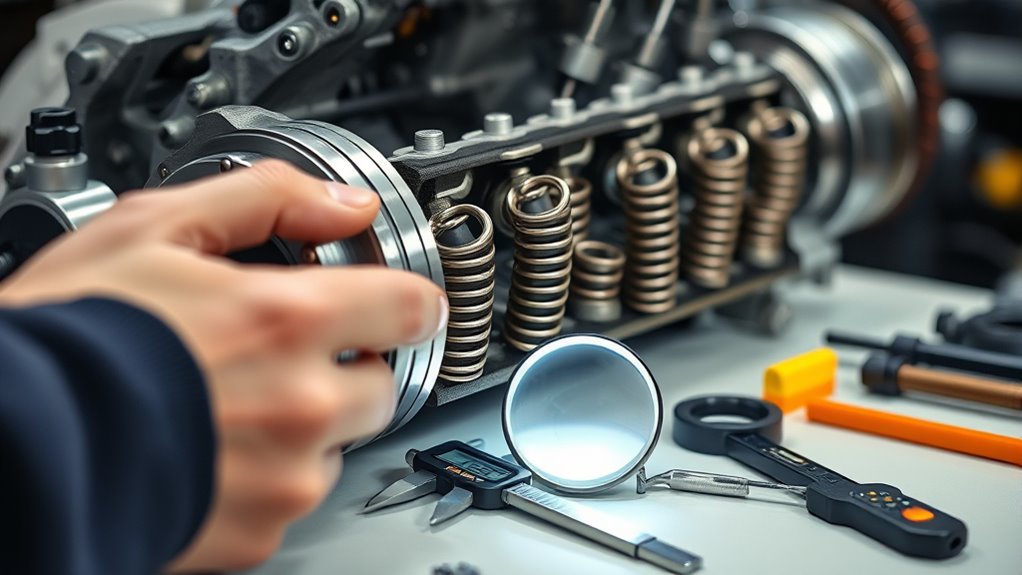

Tools and Equipment Needed for Effective Inspection

To perform an effective valvetrain inspection, you need the right tools and equipment at your disposal. A good quality flashlight helps you see hidden wear or damage during inspections. A set of precision calipers and micrometers allows you to measure valve stem and guide clearances accurately. A mirror can assist in viewing hard-to-reach areas of the valvetrain. You’ll also need basic hand tools like screwdrivers and pliers for removing components. A dial indicator is essential for checking valve lift and timing-related measurements. For more advanced inspections, a borescope can provide detailed visuals inside the combustion chamber. Ensure your tools are clean, calibrated, and in good condition to avoid misdiagnosis and ensure precise assessments during your valvetrain inspection.

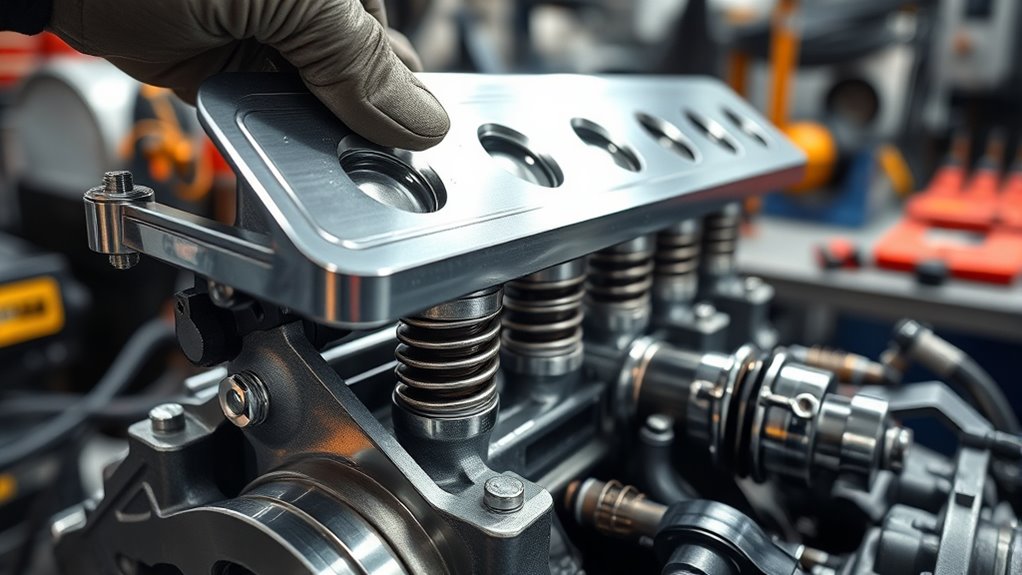

Step-by-Step Guide to Visual Inspection of Valvetrain Components

Begin your visual inspection by carefully removing any covers or components that obstruct access to the valvetrain. Once exposed, examine each component for signs of damage or wear. Look for:

Start by removing covers to visually inspect for cracks, wear, or damage on valvetrain components.

- Cracks, pitting, or burns on valves and valve seats

- Bent or broken rocker arms and pushrods

- Excessive wear or scoring on cam lobes and followers

- Loose or missing fasteners and retaining clips

Check the condition of the valve springs for cracks or corrosion. Ensure that all parts move freely without binding or unusual resistance. Keep an eye out for oil leaks or buildup that could indicate underlying issues. A thorough, detailed visual check helps pinpoint potential problems before they escalate, ensuring your engine runs smoothly at high revs. Additionally, inspecting valvetrain components can reveal early signs of wear that may affect engine performance and longevity.

Techniques for Measuring Valve Clearance and Spring Tension

To guarantee your valvetrain runs smoothly, you need to accurately measure valve clearance and spring tension. Using proper techniques helps you get precise readings and identify issues early. Let’s explore the best methods for testing these critical components. Additionally, understanding credit card terms can help you manage any unexpected costs associated with maintenance or repairs.

Precise Clearance Measurement Techniques

Accurate measurement of valve clearance and spring tension is essential for ideal engine performance and longevity. To achieve this, use precise tools like feeler gauges and dial indicators. First, verify the engine is cool and the timing is set to TDC for the cylinder you’re checking. Then, carefully insert the feeler gauge between the valve stem and rocker arm or cam. For spring tension, employ a spring compressor to measure compression force accurately. Keep these tips in mind:

- Use high-quality, calibrated gauges for consistent results

- Always verify your tools before measurement

- Measure multiple times to confirm accuracy

- Record readings carefully for future reference

Ensuring proper valvetrain maintenance contributes greatly to engine health and efficiency. Following these techniques ensures accurate clearance and tension readings, helping maintain optimal valvetrain function.

Spring Tension Testing Methods

Measuring spring tension is essential for ensuring your valvetrain operates smoothly and reliably. To test spring tension, you can use a spring compressor or a specialized spring tester. First, remove the valve spring from the cylinder head carefully. Compress the spring using the tester or compressor, then measure the force required to compress it to a specific height. Compare your reading to the manufacturer’s specifications to determine if the spring maintains proper tension. Alternatively, a dial gauge can measure spring deflection, indicating if the spring is within proper limits. Consistent tension prevents valve float and ensures accurate timing at high RPMs. Regular testing helps identify weak or worn springs before they cause engine damage, keeping your engine running smoothly and efficiently.

Diagnosing and Addressing Common Valvetrain Issues

If you notice ticking or tapping sounds from your engine, it could be a sign of valvetrain issues. Problems with valve clearance or camshaft timing often cause these noises and affect performance. Identifying these symptoms early helps you address issues before they cause more damage. Regular valvetrain inspections can help prevent costly repairs and ensure your high-revving four-stroke engine remains in optimal condition.

Ticking or Tapping Sounds

When you hear a ticking or tapping sound coming from your engine, it often indicates a valvetrain issue that needs attention. This noise can signal loose components, insufficient lubrication, or worn parts. To diagnose, start by checking for proper oil levels and quality, as low or dirty oil can cause noise. Next, inspect for loose rocker arms or pushrods, which can produce tapping sounds. You should also listen carefully to pinpoint the source—whether it’s near the cylinder head or elsewhere. Finally, consider the following:

- Worn or damaged lifters

- Improper valve clearance

- Loose or broken timing chain components

- Dirty or clogged valve train parts

- Proper maintenance practices can help prevent many common valvetrain issues and maintain engine performance.

Valve Clearance Problems

Valve clearance problems often cause engine noise, rough idling, or poor performance, making it essential to diagnose and fix them promptly. When clearance is too tight, valves may not fully close, leading to misfires, loss of power, or overheating. Conversely, too loose clearance causes tapping or ticking noises and can result in increased wear on valve components. To check clearance, remove the valve cover and use a feeler gauge to measure the gap between the rocker arm or cam lobe and the valve stem. If the clearance is outside specifications, adjust it by tightening or loosening the adjusting screws or shims. Regularly inspecting and maintaining proper valve clearance helps ensure efficient engine operation, prevents damage, and prolongs component life. Using appropriate tools and understanding the flushing mechanisms can aid in accurate adjustments and troubleshooting.

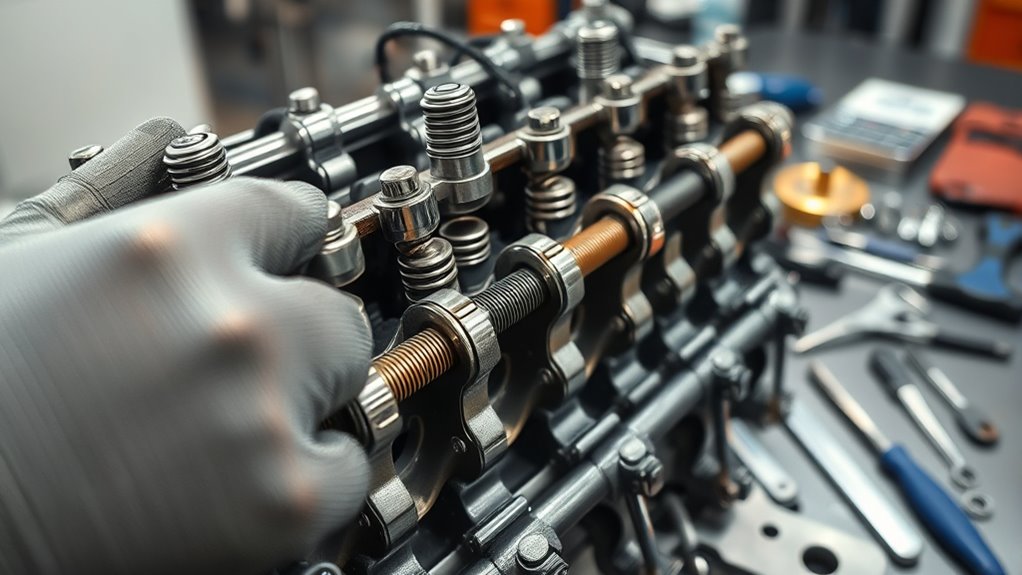

Camshaft Timing Errors

Camshaft timing errors are a common cause of valvetrain problems that can substantially affect engine performance. When timing is off, your engine may run rough, lose power, or experience misfires. To diagnose timing issues, check the timing marks and guarantee the camshaft and crankshaft are properly synchronized. Common signs include unusual engine noise, poor acceleration, and increased fuel consumption. Addressing these errors involves adjusting or replacing timing chains, belts, or sprockets. Here are some key points to consider:

- Verify timing marks align correctly during inspection

- Check for stretched or worn timing belts and chains

- Inspect sprockets and gears for damage or wear

- Re-torque tensioners to ensure proper belt tension

- Consider the impact of valvetrain tuning on engine timing and performance

Timely diagnosis and correction keep your high-revving engine running smoothly.

Preventative Maintenance Tips for High-Revving Four-Stroke Engines

Regular valvetrain inspections are essential for maintaining the performance and longevity of high-revving four-stroke engines. Consistent checks help identify wear or misadjustments before they cause serious damage. Keep an eye on valve clearances, ensuring they stay within manufacturer specs. Use quality lubricants and replace oil regularly to reduce friction and prevent deposits. Check timing belts and chains for wear, replacing them as needed to avoid sudden failures. Also, monitor valve springs for signs of fatigue, which can cause misfires at high RPMs. Incorporating tuning modifications can further optimize engine performance and reliability.

Frequently Asked Questions

How Often Should Valvetrain Inspections Be Performed on High-Rev Engines?

You should perform valvetrain inspections regularly to keep your high-revving four-stroke engine running smoothly. Typically, check them every 15,000 to 30,000 miles or during major service intervals. If you notice any unusual noises, loss of power, or rough idling, don’t wait—inspect sooner. Regular inspections help catch issues early, preventing extensive damage and ensuring peak performance at high RPMs.

Can I Perform Valvetrain Inspections Without Removing the Cylinder Head?

Ever wonder if you can check your valvetrain without removing the cylinder head? You can perform some inspections with the head still in place, like checking valve clearances or visually inspecting accessible parts. However, for a thorough examination of valves, springs, or camshafts, removing the head is usually necessary. So, while partial inspections are possible, complete assessments require removing the cylinder head for accurate results.

What Are the Risks of Ignoring Minor Valvetrain Wear Signs?

Ignoring minor valvetrain wear signs can lead to serious engine problems. You risk decreased performance, misfires, and increased fuel consumption. Worn components may fail unexpectedly, causing costly repairs and potential engine damage. If you overlook early signs, it could result in valve damage or timing issues that affect engine longevity. Regular inspections help catch wear early, saving you money and ensuring your engine runs smoothly and efficiently.

Are There Specific Brand Recommendations for Valvetrain Inspection Tools?

When you ask about brand recommendations for valvetrain inspection tools, you’re on the verge of choosing tools that could make or break your engine’s health—literally! I recommend sticking with trusted names like Snap-on, Lisle, and OEM-specific tools. These brands deliver precision and durability, ensuring you catch even the tiniest wear signs before they turn into catastrophic failures. Skimping here could cost you big in the long run.

How Does High RPM Operation Affect Valvetrain Component Lifespan?

High rpm operation puts extra stress on your valvetrain components, causing faster wear and potential damage. As you push your engine higher, parts like valves, springs, and followers endure increased forces and heat. This accelerates fatigue, leading to a shorter lifespan if you don’t regularly inspect and maintain them. Staying vigilant with timely inspections helps catch wear early, ensuring your engine stays reliable and performs efficiently at high revs.

Conclusion

By regularly inspecting your valvetrain, you catch wear early and keep your engine running smoothly. Neglect it, and small issues can become costly failures. Precision matters in high-revving engines—accuracy prevents breakdowns. Care keeps performance sharp, but neglect invites trouble. Stay vigilant, embrace routine checks, and enjoy the thrill of a well-tuned engine. After all, precision and care are your best tools for lasting power and peak performance.