To keep your engine cool in deep sand, focus on preventing sand infiltration by using sealed radiators, high-quality filters, and reinforced seals. Upgrading to larger, corrosion-resistant radiators made from aluminum or copper enhances heat dissipation. Installing additional fans or ventilation systems improves airflow. Regular maintenance, monitoring coolant temperatures, and selecting the right cooling fluids also help prevent overheating. Want to learn more about advanced solutions for tough sand conditions? Keep exploring!

Key Takeaways

- Install sealed radiators and high-quality filters to prevent sand infiltration and maintain optimal airflow.

- Use elevated radiator mounting and reinforced seals to minimize sand entry and protect cooling components.

- Consider hybrid or liquid cooling systems for superior heat management in sandy, harsh environments.

- Regularly clean radiators, inspect coolant passages, and monitor coolant temperature using sensors or gauges.

- Enhance airflow with high-capacity fans and proper ventilation to prevent overheating during deep sand driving.

Understanding the Impact of Sand on Engine Cooling

Sand can substantially affect engine cooling systems, especially in desert or sandy environments. When you drive through sandy terrain, tiny particles can infiltrate your cooling system, clogging radiators and cooling fins. This buildup reduces airflow and heat dissipation, causing your engine to overheat more easily. Sand can also settle in coolant passages, restricting fluid flow and impairing heat transfer. Additionally, the abrasive nature of sand accelerates wear on cooling system components, such as pumps and hoses. If you ignore these impacts, your engine might run hotter than it should, risking damage or failure. Regular maintenance, including cleaning radiators and inspecting for sand infiltration, becomes vital in sandy environments. Understanding how sand affects your cooling system helps you take proactive steps to keep your engine running smoothly. Moreover, using appropriate filtration can help prevent sand particles from entering sensitive parts of the cooling system.

Choosing the Right Cooling System for Sandy Terrains

When selecting a cooling system for sandy terrains, you need to prioritize sand ingress prevention to avoid damage and blockages. Consider effective cooling methods that can withstand harsh conditions, and think about maintenance and durability to guarantee long-term performance. Making the right choice helps keep your system reliable and efficient in challenging environments.

Sand Ingress Prevention

Have you considered how sandy terrains can pose a significant challenge to cooling system longevity? Sand easily infiltrates cooling components, causing blockages and wear. To prevent this, select systems with sealed radiators and filters designed for harsh environments. Proper airflow management also helps keep sand out, reducing the risk of ingress. Regular maintenance, including cleaning filters and inspecting seals, is essential. Additionally, choosing the appropriate gear shifting mechanisms can improve system efficiency in challenging terrains. Here’s a quick comparison:

| Feature | Benefit | Recommended For |

|---|---|---|

| Sealed Radiators | Prevents sand entry | Heavy sandy terrains |

| Air Filters | Traps fine particles | Frequent dusty conditions |

| Reinforced Seals | Enhances durability and sealing | Long-term sandy operation |

| Elevated Mounting | Reduces sand accumulation at entry points | Deep sand environments |

Choosing the right combination keeps your cooling system resilient, even in the harshest sandy conditions.

Effective Cooling Methods

Choosing the right cooling system for sandy terrains requires careful consideration of environmental challenges. You need a system that efficiently dissipates heat without being overwhelmed by dust and debris. Air-cooled systems are simple and lightweight but may struggle in extreme heat or when dust blocks vents. Liquid cooling offers superior heat management, maintaining engine temperature in demanding conditions, but requires a sealed system and regular maintenance. Hybrid systems combine both methods, providing flexibility in variable conditions. Additionally, using high-quality radiators and ensuring proper airflow can boost cooling performance. Your goal is to prevent overheating while minimizing vulnerability to sand intrusion. Selecting a cooling method suited to the environment guarantees your engine stays within ideal temperature ranges and performs reliably in deep sand. It’s also important to consider best cooling practices that adapt to dusty environments to enhance system longevity and efficiency.

Maintenance and Durability

Selecting a cooling system that can withstand sandy conditions means considering how easy it is to maintain and how durable it remains over time. Sand can clog radiators and cooling channels, so choose systems with accessible filters or clean-out points to simplify upkeep. Look for rugged construction and corrosion-resistant materials, ensuring the system endures harsh environments without frequent repairs. Regular inspections are essential—you should check for sand buildup and leaks often. Investing in a durable cooling system reduces downtime and repair costs, keeping your engine running smoothly in tough conditions. A well-chosen, resilient system not only handles the abrasive nature of deep sand but also minimizes maintenance efforts, helping you focus on your adventure instead of constant repairs.

Upgrading Radiators for Better Heat Dissipation

Upgrading your radiator can markedly improve heat dissipation, but you should consider material efficiency improvements to get the best performance. Enhanced cooling capacity depends on choosing the right design and features that match your system’s needs. Make sure the new radiator is compatible and fits properly to avoid any installation issues down the line. Additionally, selecting a radiator with proper material selection can significantly impact its thermal conductivity and overall effectiveness.

Material Efficiency Improvements

Enhancing radiator materials can substantially boost heat dissipation efficiency in cooling systems. Using advanced materials like aluminum or copper improves thermal conductivity, allowing heat to transfer faster from the engine. Lightweight alloys reduce overall weight, helping your vehicle perform better in deep sand conditions. Consider radiators with fins made from high-conductivity metals, which increase surface area and facilitate better airflow. Upgrading to corrosion-resistant materials extends radiator lifespan and maintains efficiency over time. Additionally, composite materials or coatings can prevent build-up and corrosion, ensuring consistent heat transfer. The choice of radiator design can also influence cooling performance by optimizing airflow and heat exchange. These material improvements not only enhance cooling performance but also reduce maintenance needs, keeping your engine cooler and more reliable during tough off-road adventures. Proper material selection is key to optimizing heat dissipation and engine longevity.

Enhanced Cooling Capacity

To improve your cooling system’s performance, upgrading your radiator can make a significant difference in heat dissipation. A larger or more efficient radiator increases surface area, allowing heat to escape faster. Consider radiators with improved fin designs or increased core thickness for better airflow and heat transfer. Upgrading can reduce engine temps and prevent overheating in deep sand conditions. Here’s why enhanced radiators matter:

| Feature | Benefit | Example |

|---|---|---|

| Larger Core | Greater heat capacity | 3-row vs. 2-row |

| High-Flow Fins | Faster heat transfer | Copper vs. aluminum |

| Increased Surface Area | Better cooling efficiency | Dual vs. single pass |

| Improved Materials | Better durability and heat conduction | Copper alloys |

| Enhanced Design | Optimized airflow | Dimpled or embossed fins |

A well-designed radiator can also incorporate advanced materials that improve overall heat conduction and longevity.

Compatibility and Fit

Choosing the right radiator for your vehicle involves ensuring it fits correctly and is compatible with your engine’s layout. Measure your current radiator’s dimensions and note mounting points to find a match. Check your vehicle’s specifications and consult manufacturer recommendations to avoid fitment issues. An improperly fitting radiator can cause leaks, block airflow, or damage other components. Verify connections like inlet and outlet sizes, as mismatched fittings can lead to coolant flow problems. If upgrading for better heat dissipation, ensure the new radiator’s size and mounting brackets align with your vehicle’s setup. Compatibility also means choosing materials that withstand deep sand conditions, like corrosion-resistant cores. Taking these steps guarantees a proper fit, maximizing cooling efficiency and preventing costly modifications or repairs down the road.

The Role of High-Performance Coolant Fluids

High-performance coolant fluids play an essential role in maintaining ideal temperatures for advanced cooling systems. They guarantee your engine runs smoothly, especially in challenging conditions like deep sand where heat builds quickly. These coolants are formulated to resist high temperatures, prevent corrosion, and maximize heat transfer. Additionally, choosing the right coolant can help mitigate issues related to AI vulnerabilities, ensuring optimal performance and safety in automated systems. Here are three key benefits:

- Enhanced Heat Dissipation: They transfer heat more efficiently, preventing overheating.

- Corrosion Resistance: Protect engine components from rust and decay.

- Extended Fluid Life: Last longer under extreme conditions, reducing maintenance needs.

Using the right high-performance coolant fluid helps your engine stay cool and reliable, even in demanding environments. It’s a small but indispensable step to keep your vehicle running at its best in deep sand terrain.

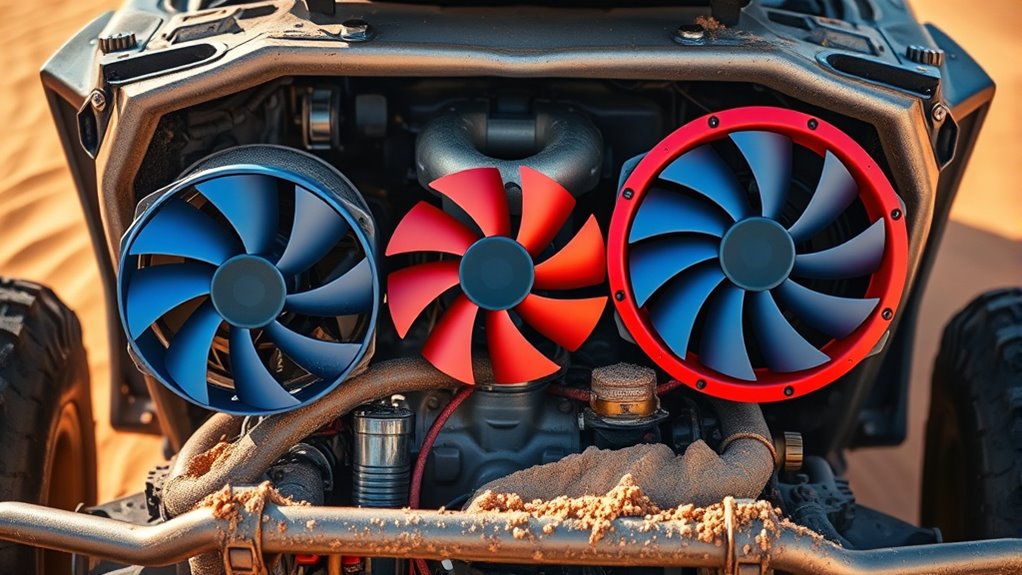

Installing Additional Cooling Fans and Ventilation Systems

Adding extra cooling fans and ventilation systems can considerably improve your engine’s ability to stay cool under demanding conditions. You’ll prevent overheating in deep sand, especially when pushing your vehicle hard. Installing auxiliary fans helps maintain airflow when the main radiator struggles, while vent systems improve heat dissipation. Choose fans based on size, noise, and power draw to match your setup. Proper placement ensures ideal cooling. Consider the table below for quick guidance:

| Fan Type | Benefits | Best Use Case |

|---|---|---|

| Electric Fan | Quick activation, adjustable | Extra boost in heat |

| Shroud Fan | Focused airflow, efficient | Radiator cooling |

| Ventilation | Reduces internal heat buildup | Cabin and engine bay |

| High-Flow Fan | Increased airflow, durability | Extreme conditions |

Additionally, incorporating proper airflow management can optimize your cooling system’s efficiency and prevent heat buildup during intense off-road activities.

Utilizing Sand-Resistant Air Filters and Intake Systems

Choosing the right filter material is key to preventing sand from clogging your system, so consider durable, fine-mesh options. The design of your intake system also plays a vital role in minimizing sand entry and optimizing airflow. Additionally, implementing proper maintenance routines can help identify and address potential issues early, ensuring consistent performance. By focusing on these aspects, you can keep your cooling system running efficiently even in sandy environments.

Filter Material Selection

Selecting the right filter material is crucial for protecting cooling systems from sand and debris, especially in harsh environments. The filter material you choose must resist clogging and withstand abrasive particles. To enhance performance, consider these options:

- Synthetic fibers – They trap fine particles effectively and dry quickly, reducing clogging.

- Foam filters – Durable and easy to clean, making them ideal for heavy-duty use.

- Specialized sand-resistant media – Engineered to repel sand and prevent buildup, maintaining airflow longer.

- Proper maintenance and timely replacement of filters are essential to prevent filter clogging and ensure optimal engine cooling performance.

Choosing the correct material ensures your engine stays cool and performs reliably. Keep in mind, the best filter material balances filtration efficiency with airflow, reducing maintenance and maximizing protection in challenging conditions. Proper selection is key to maintaining ideal engine health in deep sand environments.

Intake System Design

Have you considered how the design of your intake system can substantially improve protection against sand and debris? A well-designed intake system minimizes the risk of particles entering your engine. Use elevated or sealed air intake boxes to keep dust out, especially when driving in deep sand. Incorporate pre-cleaners or snorkels that draw air from above the vehicle to prevent sand ingestion. Position filters away from direct airflow, reducing exposure to airborne debris. Ensure flexible, sealed ducting maintains a tight fit, preventing sand from bypassing filters. Regularly inspect and clean intake components to keep the system functioning at its best. By focusing on intake system design, you can greatly extend your engine’s life and maintain peak performance even in harsh, sandy environments.

Maintaining Proper Engine Temperatures With Monitoring Devices

Monitoring devices play a crucial role in maintaining proper engine temperatures, guaranteeing your vehicle runs efficiently and preventing overheating. By keeping an eye on critical temperature readings, you can respond quickly to potential issues before they escalate. Here are three essential monitoring tools:

- Temperature Gauges: They provide real-time data on coolant temperature, helping you spot overheating early.

- Infrared Thermometers: Point these at various engine parts to check for hot spots or uneven cooling.

- Electronic Sensors: These continuously track engine temperature and send alerts if levels go beyond safe limits.

Using these devices allows you to manage engine heat proactively, especially in challenging conditions like deep sand, where temperature fluctuations can be rapid. Stay vigilant and ensure your cooling system keeps your engine happy.

Best Practices for Regular Cooling System Maintenance

Regular cooling system maintenance is essential to keep your engine running smoothly and prevent costly breakdowns. To start, check your coolant levels regularly and top them off with the recommended type. Inspect hoses for cracks, leaks, or swelling, replacing any damaged ones immediately. Flushing the cooling system periodically removes rust, debris, and old coolant that can hinder heat transfer. Make sure your radiator is clean and free of obstructions—use a gentle brush or compressed air if needed. Test your thermostat and water pump to ensure they operate correctly. Keep an eye on temperature gauges during operation, and address any abnormal readings promptly. Regular visual inspections and timely replacements help maintain ideal cooling performance, especially in challenging deep sand conditions.

Innovative Technologies in Deep Sand Cooling Solutions

Innovative technologies are transforming deep sand cooling solutions by enhancing efficiency and reliability in challenging environments. These advancements help engines stay cool even when conditions are extreme. Here are three key innovations:

- Advanced Fluid Dynamics: Engineers now use computational fluid dynamics (CFD) to optimize cooling system designs, ensuring better heat dissipation and reducing hotspots.

- Smart Cooling Systems: Sensors and automation enable real-time monitoring and adjustments, preventing overheating and reducing energy consumption.

- High-Performance Materials: New materials resist sand abrasion and corrosion, extending system lifespan and maintaining ideal cooling performance.

These technologies work together to keep engines running smoothly in deep sand, reducing downtime and maintenance costs while improving overall reliability.

Tips for Driving and Operating in Deep Sand Conditions

Driving in deep sand requires careful technique and preparation to prevent getting stuck or damaging your vehicle. Maintain a steady, momentum-driven approach—avoid sudden stops or sharp turns. Keep your tires at lower pressure to increase flotation and improve traction, but don’t go too low to avoid rim damage. Use a consistent, gentle throttle to prevent wheel spin. If you start to bog down, shift to a higher gear and keep moving forward steadily.

Here’s a quick tip:

| Tip | Why it Matters |

|---|---|

| Lower tire pressure | Increases surface area, reduces sinkage |

| Maintain momentum | Prevents loss of traction |

| Use low-range gear | Enhances control and power |

| Avoid sharp turns | Prevents digging and getting stuck |

Frequently Asked Questions

How Does Ambient Temperature Affect Engine Cooling in Sandy Environments?

Ambient temperature directly impacts your engine’s cooling efficiency in sandy environments. When it’s hot outside, your engine struggles to dissipate heat, risking overheating. Cooler temperatures help your cooling system work more effectively, maintaining ideal engine temperatures. You should pay extra attention to cooling system maintenance in high temperatures, ensuring fans, radiators, and coolant levels are in good shape. Staying mindful of ambient conditions helps prevent engine damage and keeps your vehicle running smoothly.

What Are the Signs of Overheating Specific to Engines in Deep Sand?

When your engine overheats in deep sand, you’ll notice it running rough or losing power quickly. You might see steam or smoke from the radiator or notice the temperature gauge climbing into the red zone. The engine may also emit a burning smell or feel excessively hot to the touch. If you ignore these signs, engine damage could occur, so stop and cool down immediately to prevent serious problems.

Can Aftermarket Cooling Systems Void Vehicle Warranties?

Imagine your engine as a delicate dance partner; replacing its cooling system might seem like enhancing performance, but it can also risk voiding your vehicle’s warranty. Many manufacturers consider aftermarket cooling systems as modifications, which can lead to warranty denial if issues arise. Always check your vehicle’s warranty terms and consult with your dealer before making upgrades, so you can enjoy your adventure without unexpected setbacks.

How Often Should Cooling System Components Be Inspected in Sandy Conditions?

You should inspect your cooling system components more frequently in sandy conditions, ideally every 3,000 to 5,000 miles or every few months. Sand can clog radiators, fans, and hoses, leading to overheating. Regular checks verify coolant levels are adequate, hoses are intact, and the radiator is clean. Staying vigilant helps prevent engine damage, especially when driving in deep sand, keeping your vehicle running smoothly and reliably.

Are There Eco-Friendly Cooling Options Suitable for Deep Sand Terrains?

Ever wondered if eco-friendly cooling options can handle deep sand terrains? You can choose biodegradable coolants made from natural ingredients, which reduce environmental impact while protecting your engine. Solar-powered cooling fans or evaporative cooling systems also offer sustainable alternatives. These options help keep your engine cool without harming the environment. Are you ready to upgrade your cooling system to be more eco-conscious and efficient in challenging sandy conditions?

Conclusion

Just like a well-tuned engine running smoothly through deep sand, your cooling system keeps your vehicle happy and reliable. By choosing the right components, staying on top of maintenance, and using innovative tech, you’ll prevent overheating and keep your adventures going. Remember, ignoring your cooling system is like ignoring a leaking tire—eventually, it’ll cause trouble. Stay proactive, and your engine will perform like a sandstorm’s eye—calm and unstoppable.