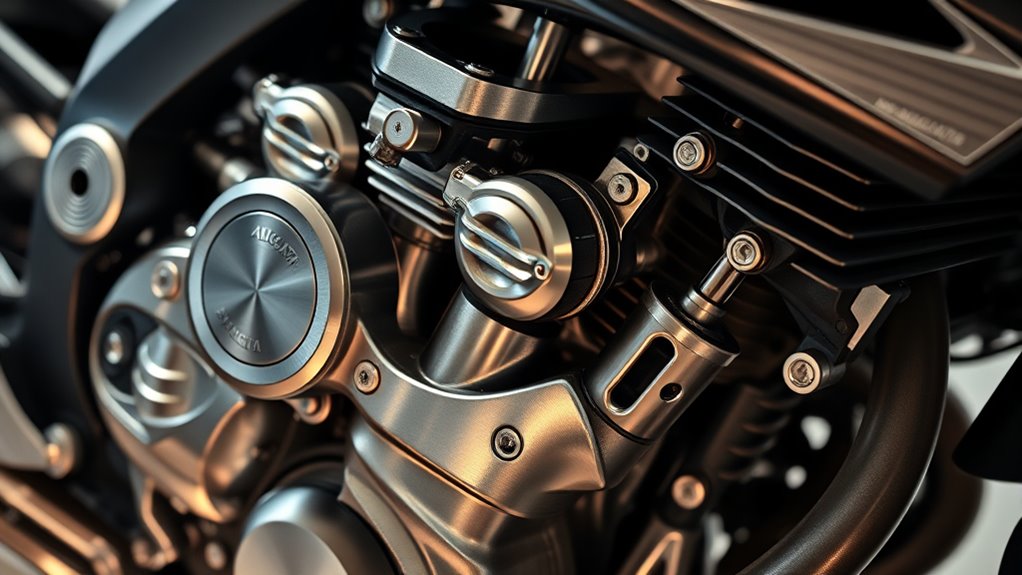

MV Agusta’s engine balancing under stress is carefully managed through advanced engineering to keep vibrations in check during high performance. The company uses dynamic balancing techniques and precise component alignment, ensuring your bike remains smooth and stable when pushing limits. This focus on balance reduces wear and tear, prolongs engine life, and boosts safety. To discover how MV Agusta maintains this peak performance under pressure, continue exploring the techniques behind their engineering mastery.

Key Takeaways

- MV Agusta employs advanced dynamic balancing techniques to ensure engine components remain aligned under high stress.

- Precision machining minimizes imbalances, maintaining smooth operation during rapid acceleration and high revs.

- The brand designs engines to dampen vibrations, reducing fatigue and potential component failure.

- Robust balancing of pistons, crankshafts, and connecting rods enhances durability under demanding riding conditions.

- These engineering strategies optimize stability, engine responsiveness, and longevity during stressful performance scenarios.

When engines are pushed to their limits, maintaining proper balance becomes essential to guarantee performance and longevity. You need to pay close attention to how the engine manages vibrations, especially when operating under high stress. Vibration reduction isn’t just about comfort; it’s about safeguarding the engine’s structural integrity. Excessive vibrations can lead to metal fatigue, loosened fasteners, and even critical component failure over time. As you rev the engine harder, you might notice increased vibrations, which can threaten the bike’s stability and your safety. That’s why MV Agusta invests heavily in precise engine balancing techniques, ensuring that every component works harmoniously to minimize unwanted movement.

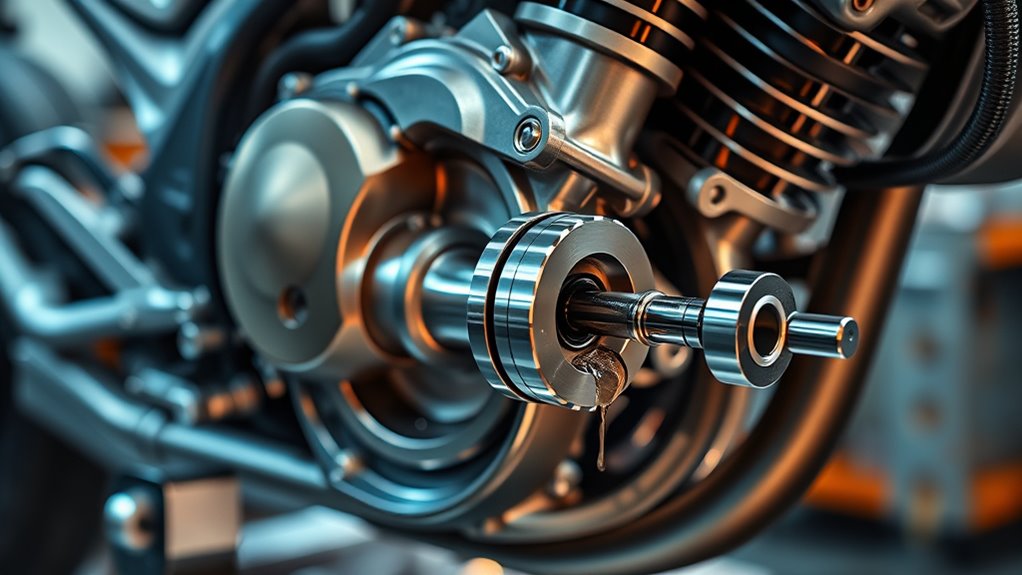

Achieving ideal engine balance involves carefully aligning internal parts like pistons, crankshafts, and connecting rods. When these elements are out of sync, vibrations intensify, causing uneven wear and reducing the engine’s lifespan. You can think of it like a well-orchestrated dance—each part must move in perfect harmony to avoid unnecessary stress. During high-performance riding, engine components experience rapid acceleration and deceleration, which amplifies the importance of vibration mitigation. If you neglect this balance, the engine’s structural integrity could be compromised, leading to costly repairs or even catastrophic failure.

MV Agusta’s engineering team employs advanced techniques such as dynamic balancing and precision machining to ensure every engine component is perfectly aligned. This meticulous process reduces vibrations at their source, rather than just damping them afterward. The result is an engine that not only performs at peak levels but also maintains its durability over time. When you feel the smoothness during acceleration, you’re experiencing the benefits of these carefully calibrated balances. It’s not just about power; it’s about maintaining that power reliably under stress without sacrificing the bike’s long-term health.

Furthermore, a balanced engine reduces the fatigue load on critical parts like bearings and mounts. This means less wear and tear, and ultimately, a longer-lasting engine. You’ll notice that your MV Agusta remains responsive and stable, even during aggressive riding sessions. Proper vibration reduction techniques help preserve the structural integrity of the entire engine assembly, ensuring that each component can withstand the rigors of high-speed performance. When you’re riding at the edge, the last thing you want is your engine to be a ticking time bomb of imbalance. Thanks to MV Agusta’s focus on precise balancing, you can push your motorcycle further, knowing it’s built to handle stress without compromising its core strength. Engine balancing techniques are vital in achieving this durability and performance.

Frequently Asked Questions

How Does Engine Balancing Improve Overall Motorcycle Performance?

Engine balancing improves your motorcycle’s performance by reducing vibrations, which makes your ride smoother and more comfortable. When vibrations are minimized, your engine runs more efficiently, leading to better power optimization. This means you get enhanced acceleration, stability, and control, especially at high speeds. By maintaining proper balance, you also decrease wear and tear on engine parts, extending your bike’s longevity and ensuring a reliable, high-performance ride every time you hit the road.

What Are Common Signs of Engine Imbalance in MV Agusta Bikes?

You’ll notice engine imbalance in your MV Agusta through unusual vibration patterns, which become more pronounced at certain RPMs, and noise fluctuations that sound off from normal engine hum. In fact, studies show that improperly balanced engines can increase vibrations by up to 30%, affecting comfort and performance. If you feel these signs, it’s a clear indicator that your bike needs a check, as imbalance can lead to long-term damage.

How Often Should Engine Balancing Be Performed on Stressed Engines?

You should perform engine balancing on stressed MV Agusta engines during regular maintenance intervals, typically every 6,000 to 8,000 miles, or if you notice increased vibrations. Vibration monitoring helps detect imbalance early, so address issues promptly. If you ride aggressively or in demanding conditions, consider more frequent checks. Consistent balancing guarantees smooth operation, reduces wear, and prolongs engine life, keeping your bike performing at its best.

Does Engine Balancing Affect Fuel Efficiency?

Engine balancing directly impacts your bike’s fuel economy and performance gains. When your engine is well-balanced, it runs smoother, reducing vibrations and resistance, which helps you conserve fuel. Misaligned or unbalanced engines, especially under stress, can waste energy and decrease efficiency. Regular balancing ensures peak performance, so you get better fuel economy and smoother rides. Keep your engine balanced to maximize both power and efficiency on every ride.

Are There Specific Tools Used for Balancing Under Stress Conditions?

Think of balancing tools as the maestro’s baton guiding your engine’s harmony. You’ll use specialized devices like vibration analysis sensors and calibration tools to fine-tune under stress. These tools detect subtle imbalances and help calibrate sensors precisely, ensuring smooth operation. With this approach, you can maintain ideal engine performance, even under demanding conditions, by addressing vibrations early and keeping everything running in perfect symphony.

Conclusion

You can almost see the engine’s relentless heartbeat, pounding like a thunderstorm inside your bike under stress. Every vibration, every tremor, is perfectly tamed by MV Agusta’s masterful balancing, turning chaos into symphony. It’s as if the engine’s stress becomes a dance, a fierce yet graceful ballet that defies nature’s chaos. When you ride, you’re not just riding—you’re commanding a beast that’s been tamed to roar with perfect harmony.