If you want the best braided brake lines for superior stopping power in 2025, I recommend lines made with braided stainless steel for durability, corrosion resistance, and high performance. Look for options with PTFE lining that prevents fluid expansion and maintains consistent brake feel, even under heavy use. Vehicle-specific lines with proper fittings, quality construction, and DOT approval guarantee safety and reliability. Keep going to discover top picks and how to choose the right lines for your setup.

Key Takeaways

- High-quality braided stainless steel lines improve brake responsiveness by reducing line expansion under pressure.

- Compatibility with various vehicle types and fittings ensures secure, precise installation for optimal stopping power.

- Advanced construction features like PTFE lining and weather-resistant coatings enhance durability and performance.

- DOT-approved options meet safety standards, ensuring reliable braking in demanding conditions.

- Customer reviews highlight top performance, easy installation, and long-term reliability in 2025 models.

Allstar Performance Braided Brake Line with Size-3 Hose and End

If you’re looking for a durable and reliable braided brake line for high-performance applications, the Allstar Performance Braided Brake Line with Size-3 Hose and End is an excellent choice. This 12-inch line features a stainless steel braid and black vinyl coating, offering strength and corrosion resistance. The PTFE lining guarantees minimal fluid expansion and high-temperature stability, making it perfect for racing or demanding environments. Straight female fittings on both ends provide easy installation and compatibility with Size-3 fittings. Weighing just 1.6 ounces, it’s lightweight yet durable. Made in the U.S., this line combines quality, performance, and affordability for those serious about their braking systems.

Best For: racing enthusiasts, performance car builders, and anyone needing a durable, high-quality brake line for demanding environments.

Pros:

- Strong braided stainless steel exterior for enhanced durability and corrosion resistance

- PTFE lining ensures minimal fluid expansion and high-temperature performance

- Easy to install with straight female fittings compatible with Size-3 fittings

Cons:

- Only available in 12-inch length, which may require additional lines for larger setups

- Slightly higher cost compared to standard rubber brake lines, though justified by quality

- Limited color options, primarily black vinyl coating, for those seeking custom aesthetics

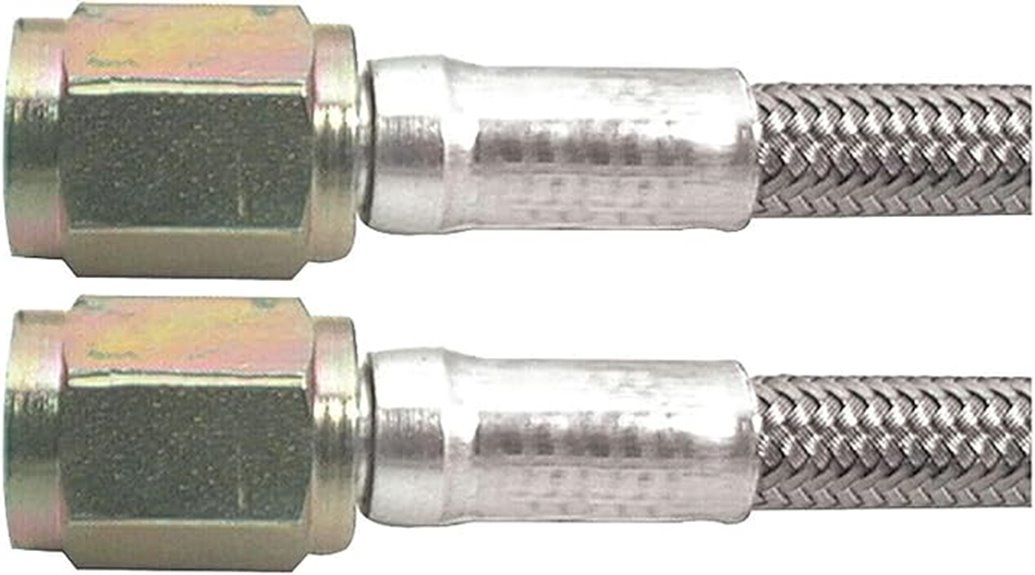

Allstar Performance 3 AN Braided Stainless Hose Assembly

The Allstar Performance 3 AN Braided Stainless Hose Assembly stands out as an excellent choice for automotive enthusiasts and racers seeking high-performance brake and hydraulic clutch lines. Measuring 12 inches, this hose features a durable braided stainless steel exterior with a PTFE lining, ensuring strength, flexibility, and chemical resistance. Compatible with 3 AN fittings, it’s ideal for high-pressure brake systems and clutch lines. Made in the USA, it’s praised for its perfect fit, reliability, and ease of installation. With over 745 reviews rating it 4.6 stars, users trust its performance for demanding applications, making it a top contender for racing and custom builds.

Best For: automotive enthusiasts, racers, and DIY mechanics seeking durable, high-performance brake or hydraulic clutch lines for racing, off-road, or custom vehicle builds.

Pros:

- Made from braided stainless steel with PTFE lining for durability and chemical resistance

- Compatible with 3 AN fittings, suitable for high-pressure brake and hydraulic systems

- Highly rated with over 745 reviews and a 4.6-star average for reliability and ease of installation

Cons:

- Limited to 12-inch length, which may not suit all custom applications

- Some users have questioned labeling or specific use restrictions, such as off-road only designation

- As a specialized part, it may be more expensive than generic hoses for casual or non-performance use

Allstar Performance 72-Inch AN Hose Assembly

The Allstar Performance 72-Inch AN Hose Assembly stands out as an excellent choice for enthusiasts needing durable and flexible brake lines. Its 72-inch length, braided stainless steel construction, and PTFE lining guarantee reliable performance and chemical resistance. The fittings include 4 AN straight female connectors on both ends, making it versatile for various vehicle setups. Designed with an external machined finish, it looks professional and high-quality. Weighing just 5.8 ounces, it’s lightweight yet sturdy. Made in the USA, this hose assembly has earned positive reviews for its durability and performance, making it a solid option for superior stopping power.

Best For: car enthusiasts and professionals seeking durable, flexible brake lines for vehicle-specific applications.

Pros:

- Made from high-quality stainless steel with PTFE lining for durability and chemical resistance

- 72-inch length provides ample flexibility for various vehicle setups

- External machined finish offers a professional appearance and high performance

Cons:

- Some users have reported shipping damage, such as kinked lines, due to packaging issues

- Limited to specific fittings (4 AN straight female connectors) which may require additional adapters for certain setups

- Slightly heavier at 5.8 ounces, which may be a consideration for weight-sensitive applications

Rough Country Brake Lines for Jeep Wrangler JK (2007-2018)

Rough Country Brake Lines stand out as an excellent upgrade for Jeep Wrangler JK owners with 4-6 inch lifts, offering durable stainless steel construction and braided protection that resist off-road damage. Made with a Teflon inner layer and a tough outer shell, these lines prevent expansion for consistent braking. They’re DOT approved and easy to install without drilling, using high-quality fasteners to ensure leak-free operation. While some users find they may be slightly short on stock or no-lift vehicles, proper routing and minor modifications help. Backed by a lifetime warranty and praised for durability, they’re a reliable choice for enhanced safety during off-road adventures.

Best For: Jeep Wrangler JK owners with 4-6 inch lifts seeking durable, high-performance brake lines to improve off-road safety and braking reliability.

Pros:

- Made from stainless steel with braided exterior for enhanced durability and resistance to debris and off-road damage

- Easy to install without drilling, with high-quality fasteners for leak-free operation

- Backed by a lifetime replacement warranty, ensuring long-term support and reliability

Cons:

- May be slightly short for stock or no-lift vehicles, requiring routing modifications or relocation brackets

- Some users report length limitations, especially on larger lifts, necessitating careful installation planning

- Potential for flexing or damage if not properly routed and reinforced during installation

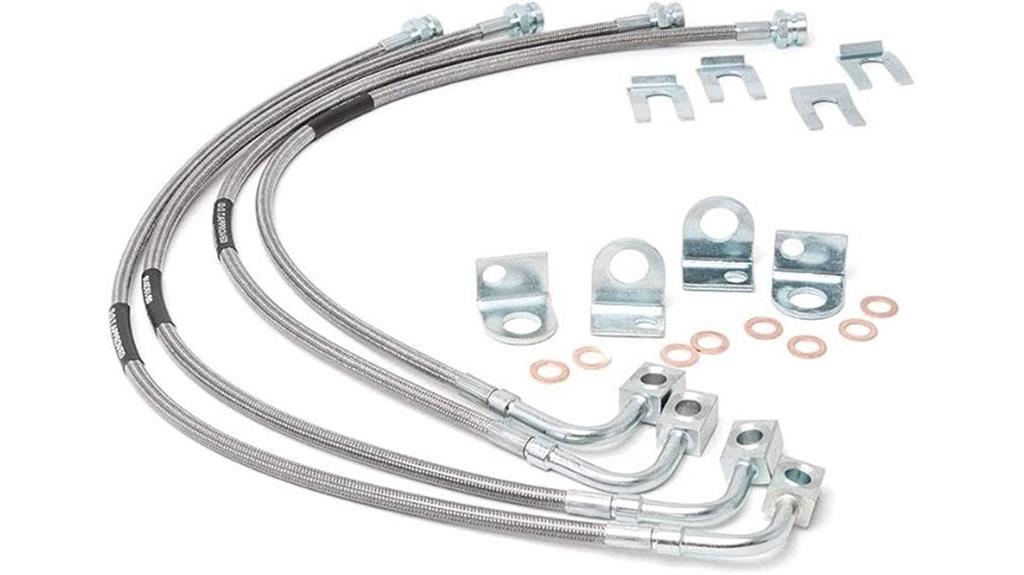

Allstar Stainless Steel Brake Hose Kit for GM Vehicles

If you’re working on a GM vehicle and need a durable, corrosion-resistant brake line upgrade, the Allstar Stainless Steel Brake Hose Kit is an excellent choice. Designed specifically for GM metric brake vehicles, it fits bolts from 10mm to 1.5 inches. Made of stainless steel, these braided lines provide increased durability and resistance to rust. The kit includes two 16-inch hoses with banjo fittings, bolts, washers, frame adapters, tabs, and clips—all D.O.T. approved and sold as a complete set. It’s a reliable upgrade that enhances braking performance and longevity, ensuring safer, more responsive stops.

Best For: DIY enthusiasts and professional mechanics seeking a durable, corrosion-resistant upgrade for GM vehicle brake systems.

Pros:

- Made of high-quality stainless steel for enhanced durability and rust resistance

- Complete kit with all necessary fittings and accessories included

- D.O.T. approved for safety and compliance

Cons:

- May require specific tools or expertise to install properly

- Slightly higher cost compared to standard rubber hoses

- Designed specifically for GM vehicles, limiting versatility for other makes

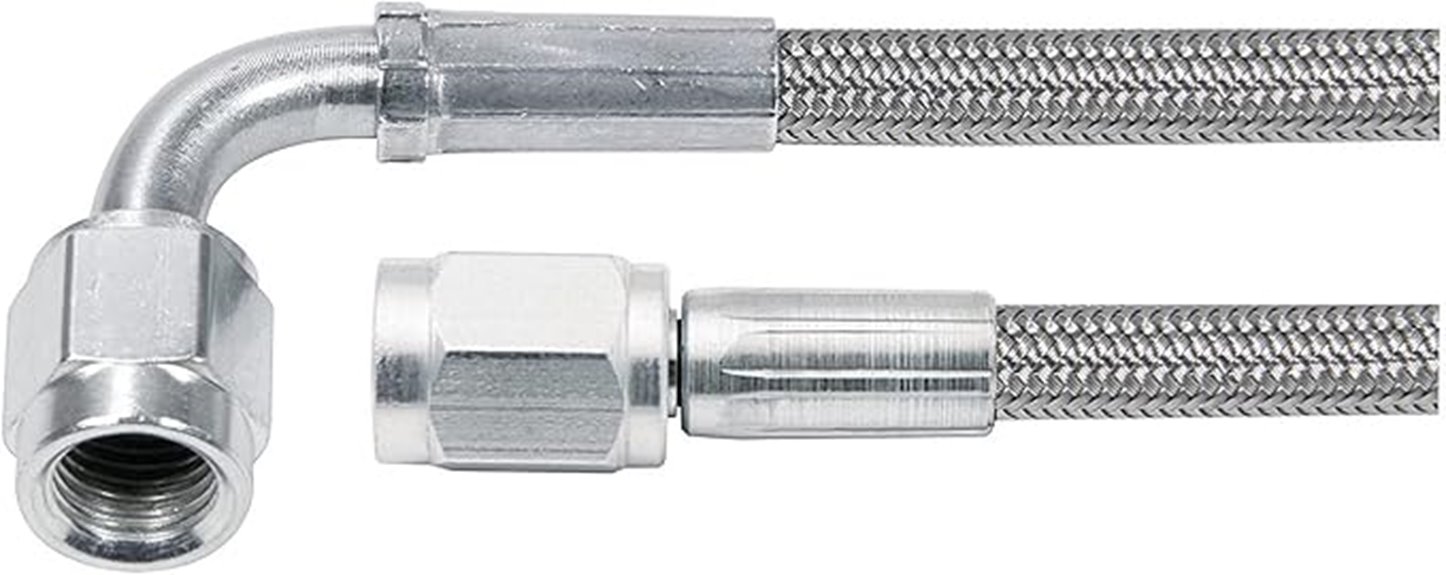

Allstar Performance AN Hose Assembly, 24 in Long

Looking for a reliable braided brake line that combines durability with precise fitment? The Allstar Performance AN Hose Assembly, 24 inches long, is an excellent choice. Made with braided stainless steel and a PTFE lining, it offers high resistance to chemicals and pressure. The assembly includes straight female and 90-degree fittings for easy installation. Exterior machining guarantees a snug fit, enhancing performance in demanding automotive applications. Backed by Allstar’s reputation, this hose is ideal for replacement brake lines and hydraulic parts. Its compact size and quality construction make it a dependable option for those seeking superior stopping power in their vehicle upgrades.

Best For: automotive enthusiasts and professionals seeking a durable, high-performance braided brake or hydraulic line for reliable vehicle upgrades.

Pros:

- Made with braided stainless steel and PTFE lining for excellent chemical and pressure resistance

- Includes both straight and 90-degree fittings for versatile installation

- Exterior machining ensures a snug, secure fit and enhanced durability

Cons:

- Price may vary across different retailers, potentially higher than generic options

- Some users have reported leaks from crimped ends if not installed properly

- The lightweight design (0.01 ounces) might be an error or misprint, making actual handling and durability assessment difficult

StopTech 950.44007 Stainless Steel Braided Brake Hose Kit Front

The StopTech 950.44007 Stainless Steel Braided Brake Hose Kit Front is an excellent choice for drivers seeking enhanced braking performance and reliability. Its construction features a PTFE inner line wrapped in stainless steel braid and coated with abrasion-resistant PVC, offering maximum protection against chafing. These hoses guarantee consistent brake pressure, delivering quicker, firmer pedal response for safer stopping. Compatible with many models like the 2004 Toyota Tundra and 98 4Runner, installation is straightforward with included fittings and brackets. Customers report improved pedal feel, responsiveness, and durability, making this kit a dependable upgrade for those wanting confident, superior stopping power.

Best For: drivers seeking to upgrade their vehicle’s braking system for improved safety, responsiveness, and durability, especially those with compatible models like Toyota Tundra and 4Runner.

Pros:

- Provides consistent brake pressure for quicker, firmer pedal response

- Constructed with durable PTFE inner line and stainless steel braid for long-lasting performance

- Easy installation with included fittings and brackets, suitable for many compatible vehicles

Cons:

- Slightly shorter length than OEM hoses may require careful measurement before purchasing

- Some users experience challenges with customer support response times

- Minor aesthetic issues such as DOT labels rubbing off, which do not affect function

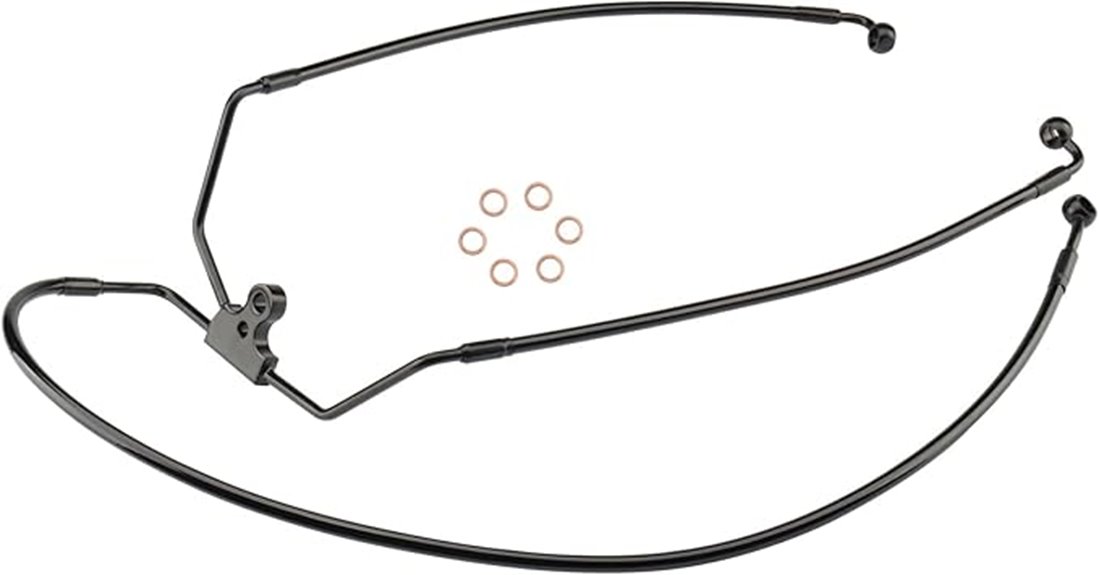

TeraFlex 4350310 30 Rear Brake Line Kit with Hardware

The TeraFlex 4350310 30 Rear Brake Line Kit stands out as an excellent choice for Jeep JK owners with lifted vehicles, especially those requiring extra length and durability. Made in the USA, these stainless steel braided lines meet MVSS-1006 standards and are DOT approved, ensuring safety and reliability. Designed for 3-4 inch lifts, they provide a firmer pedal feel and better braking response, resisting rust and corrosion. The kit’s longer lines accommodate lifted suspensions, making installation smoother. Available in silver or black, they fit specific models like 2012-2016 JKs and enhance braking performance, especially when upgrading or replacing worn stock lines.

Best For: Jeep JK owners with 3-4 inch lifts seeking durable, corrosion-resistant brake lines that improve braking response and pedal feel.

Pros:

- Made in the USA with high-quality stainless steel braided construction for durability

- Meets MVSS-1006 standards and DOT approved for safety and reliability

- Longer lines provide extra clearance for lifted suspensions, easing installation

Cons:

- May require slight bending or adjustment of hard lines during installation

- Slightly higher cost compared to stock lines, around $170 CAD

- Some users experience minor bracket misalignments or fitting adjustments

Allstar Performance 48-inch Braided Stainless Brake Hose

Designed for enthusiasts who demand durability and reliable performance, the Allstar Performance 48-inch Braided Stainless Brake Hose features a tough braided stainless steel outer layer that resists abrasion and corrosion. Its 48-inch length and 3 AN fittings—one straight, the other configurable—make installation versatile. The PTFE-lined inner hose withstands all brake fluids, offering superior durability over rubber hoses, especially under bending and flexing conditions. Made in the USA, it weighs around 4.2 ounces and fits various vehicles like Dodge W250 and Nissan 240sx. Customers praise its build quality, ease of installation, and consistent performance, making it a top choice for demanding braking systems.

Best For: automotive enthusiasts and professional mechanics seeking a durable, corrosion-resistant brake hose for custom or demanding braking systems.

Pros:

- Made with braided stainless steel outer layer for superior abrasion and corrosion resistance

- PTFE-lined inner hose compatible with all brake fluids, ensuring long-lasting performance

- Easy to install with versatile fittings, suitable for various vehicle applications

Cons:

- Slightly longer than some applications may require, potentially needing length adjustments

- Weight of approximately 4.2 ounces may be marginally heavier than rubber hoses

- Limited length options; primarily available in 48 inches, which may not suit all setups

Allstar Performance ALL46400-18 18 4 AN Braided Brake Line

If you’re looking for a durable and flexible braided brake line that fits a variety of vehicle setups, the Allstar Performance ALL46400-18 is an excellent choice. This 18-inch line features a stainless steel braid and PTFE lining, offering resistance to abrasion and corrosion while maintaining compatibility with all brake fluids. It has one straight end and customizable fittings—straight, 45°, or 90°—for versatile installation. Weighing just 2.82 ounces, it’s lightweight and easy to handle. Manufactured in the USA, it’s highly praised for its quality, flexibility, and reliable performance in custom or demanding brake systems.

Best For: DIY enthusiasts and professional mechanics seeking a durable, flexible, and reliable braided brake line for custom or high-performance vehicle setups.

Pros:

- Made with stainless steel braid and PTFE lining for excellent abrasion and corrosion resistance.

- Versatile fittings including straight, 45°, and 90° options for customized installation.

- Lightweight design (approximately 2.82 ounces) simplifies handling and installation.

Cons:

- Requires thread sealant or tape during installation to ensure optimal sealing.

- Length is fixed at 18 inches, which may not suit all vehicle configurations.

- Fittings are sold separately, so additional components may be needed for complete setup.

StopTech (950.62500) Brake Line Kit, Stainless Steel

For Corvette owners seeking reliable and high-performance brake lines, the StopTech (950.62500) Stainless Steel Brake Line Kit stands out as an excellent choice. Made in the USA, it features stainless steel braided lines that deliver quicker, firmer pedal response and improved brake modulation, especially during threshold braking. Each kit includes all necessary brackets and fittings tailored for durability and proper fit. With a maximum pressure capacity of 4500 PSI, these lines resist swelling, softening, and corrosion, resulting in a more consistent pedal feel. Easy to install and highly rated, this kit enhances braking performance for Corvette enthusiasts seeking safer, more precise stopping power.

Best For: Corvette owners seeking durable, high-performance brake lines to improve pedal feel, response, and safety during demanding driving conditions.

Pros:

- Made from stainless steel braided lines for durability and resistance to corrosion and swelling

- Provides quicker, firmer, and more consistent pedal response, especially during threshold braking

- Includes all necessary brackets and fittings for an easy, complete installation

Cons:

- Some users reported fitting separation shortly after installation, leading to brake failure

- Installation may require careful attention to prevent fitting issues or damage

- Price and availability can vary, and improper installation might affect performance

12 Handlebars Extension Front Brake Line for Harley 1996-2013 Touring Models

The Handlebar Extension Front Brake Line for Harley 1996-2013 Touring Models stands out as an excellent upgrade for riders installing taller ape hanger or custom handlebars. This 12-inch braided line is compatible with various Harley models, including Road King, Street Glide, and Electra Glide, excluding ABS versions. Made with PTFE-lined inner tubing and stainless steel braid, it offers durability and smooth fluid transfer. Its weather-resistant black PU coating resists rust and debris, ensuring longevity. The kit includes all necessary components for straightforward installation, providing a perfect fit and enhanced appearance—especially on custom setups—while maintaining ideal braking performance.

Best For: riders with Harley touring models aged 1996-2013 seeking a durable, easy-to-install upgrade for taller handlebars that maintains optimal braking performance.

Pros:

- Made with high-quality PTFE-lined inner tubing and stainless steel braid for durability and smooth fluid flow

- Weather-resistant black PU coating resists rust, abrasion, and debris, extending lifespan

- Includes all necessary components for a straightforward, hassle-free installation

Cons:

- Compatibility limited to non-ABS Harley touring models from 1996-2013

- May require minor bending or adjustments of steel lines during installation

- 12-inch length might need trimming for specific handlebar setups

The Stop Shop Universal Braided Brake Hoses

Designed for versatility, the Stop Shop Universal Braided Brake Hoses suit a wide range of vehicles, making them an ideal choice for DIY enthusiasts and professional mechanics alike. These 18-inch stainless steel braided hoses feature a 10mm banjo hole and a 3/8-24 female flare end, fitting many brake setups, including GM and classic trucks. Made in the USA, they offer durability, reliable performance, and a sleek appearance. Customers praise their quality, easy installation, and proper fitment—though selecting the right banjo bolt is essential. With a 4.4-star rating from over 150 reviews, they’re a solid, cost-effective upgrade for improved braking performance.

Best For: DIY enthusiasts and professional mechanics seeking durable, universal braided brake hoses compatible with a variety of vehicles and brake setups.

Pros:

- Constructed with braided stainless steel for durability and high performance

- Easy to install with proper fitment, suitable for multiple vehicle applications

- Made in the USA with positive customer reviews highlighting quality and reliability

Cons:

- Hardware such as banjo bolts is not included and must be purchased separately

- Compatibility depends on correct banjo bolt size; incorrect selection may cause fitment issues

- Not vehicle-specific, requiring buyers to verify length and fitting details before purchase

Rough Country GM Front Brake Lines for 2007-2019 1500/11-19 2500/3500HD

If you’re lifting your 2007-2019 Chevrolet Silverado 1500 or 2500/3500HD, Rough Country GM Front Brake Lines (Model 89370) stand out as an excellent upgrade choice. These DOT-approved stainless steel braided hoses are designed specifically for lifted trucks with 5-7.5 inch lifts, providing the extra length needed for proper clearance. Crafted from durable stainless steel with a Teflon inner layer, they resist corrosion, debris, and high-pressure expansion. Easy to install with factory clips, they improve braking performance and reliability, especially on lifted trucks. Plus, with a lifetime warranty, they’re a solid investment for enhancing your vehicle’s stopping power.

Best For: lifted 2007-2019 Chevrolet Silverado 1500 and 2500/3500HD owners seeking durable, high-performance front brake lines for improved safety and reliability.

Pros:

- Made from durable stainless steel with corrosion-resistant coating, ensuring long-lasting performance

- Designed specifically for 5-7.5 inch lifted trucks, providing proper length and fitment without modifications

- Easy to install using factory clips, with no cutting required, and offers a noticeable upgrade over rubber hoses

Cons:

- Lines are not labeled for driver or passenger side, requiring measurement or testing during installation

- Slightly smaller in diameter than stock hoses, which may require crimping brackets for secure mounting

- Does not include mounting hardware, so proper measurement and additional parts may be necessary

The Stop Shop Universal Rear Braided Stainless Brake Hose

For those upgrading their vehicle’s brake system, the Stop Shop Universal Rear Braided Stainless Brake Hose offers a reliable and durable solution. Made in the USA, it measures 21 inches and fits various vehicles, including trucks and classic cars, with compatible inlet sizes and fittings. Constructed from braided stainless steel, it enhances performance and longevity while reducing leak points. The hose includes adapters for different line sizes and features a mounting block with two ports for easy installation. Customer ratings average 4.8 stars, reflecting its quality and fit. Proper measurement of length and inlet size is essential for a perfect match, making it a versatile upgrade.

Best For: DIY enthusiasts and vehicle restorers seeking a durable, easy-to-install braided stainless brake hose compatible with various trucks and classic cars.

Pros:

- Made in the USA with high-quality braided stainless steel for durability and performance

- Includes fittings and adapters for multiple line sizes, simplifying installation

- Highly rated at 4.8 stars for quality, fit, and ease of use

Cons:

- Proper measurement of hose length and inlet size is crucial; incorrect sizing may require additional adapters

- Not vehicle-specific, which may require careful compatibility checks before purchase

- Some users found the need to buy extra adapters for 3/16-inch lines, as only 1/4-inch fittings are included by default

Factors to Consider When Choosing Braided Brake Lines

When choosing braided brake lines, I focus on material durability, resistance to wear, and how well they match my vehicle’s system. I also consider ease of installation, proper length, fitting options, and how well they stand up to weather and corrosion. These factors help me select lines that are reliable, easy to install, and suited to my driving conditions.

Material Durability and Resistance

Choosing braided brake lines with durable materials is essential because they need to withstand harsh conditions and frequent use. Most high-quality lines are made from stainless steel or similar materials that resist corrosion, rust, and wear. The outer braided layer adds abrasion resistance, protecting the inner lining from physical damage during rough driving or debris exposure. Inside, materials like PTFE provide chemical resistance and help minimize fluid expansion under high pressure, ensuring consistent braking performance. Durable materials also maintain their structural integrity over time, even under extreme temperatures. Good braided lines are designed to endure repeated flexing, bending, and exposure to debris without cracking or losing effectiveness. Prioritizing material durability guarantees reliable performance and extends the lifespan of your brake system.

Compatibility With Vehicle Systems

Selecting braided brake lines that are compatible with your vehicle’s systems is essential for guaranteeing safe and reliable performance. First, check that the fittings match your brake system’s specifications, such as size and thread type—whether it’s 10mm, 3/8-24, or AN fittings. Next, confirm the line length and bend radius suit your vehicle’s mounting points and suspension setup to prevent stress or interference. It’s also important to verify that the inner lining material, whether PTFE or rubber, is compatible with your brake fluid. Additionally, ensure the pressure rating exceeds your system’s maximum operating pressure to maintain safety. Finally, examine the connection types—straight, 45°, or 90° fittings—to ensure they fit your existing hardware and mounting locations seamlessly.

Flexibility and Installation Ease

Flexibility and ease of installation are key benefits of braided brake lines. Their flexible stainless steel braiding makes routing through tight or complex engine bays straightforward, reducing installation time. The internal PTFE lining maintains consistent flexibility, preventing kinks or cracks under pressure or during installation. Many braided lines come with customizable fittings and lengths, ensuring a precise fit and simple connection to existing brake components. The outer braid adds durability and abrasion resistance, protecting the line during installation, especially in off-road or high-performance settings. Additionally, features like straight or angled ends make installation easier across various vehicle configurations, often eliminating the need for extensive modifications. Overall, these qualities make braided brake lines a practical upgrade that combines performance with user-friendly installation.

Length and Fitting Options

Getting the length and fitting options right is essential to guarantee your braided brake lines fit properly and function reliably. I recommend measuring your existing lines carefully to ensure the new ones aren’t too tight or too slack, especially if you’ve lifted or customized your vehicle. Fitting options should match your brake hardware, like 3 AN, 4 AN, or specific thread sizes such as 10mm or 3/8-24 flare. Many braided lines offer ends that are straight, 45°, or 90°, which help route the lines neatly and avoid interference. When upgrading or lifting, longer lines might be necessary to prevent strain during suspension travel. Accurate measurements and understanding your vehicle’s inlet and outlet sizes will help you select compatible fittings, making installation smoother and ensuring reliable braking performance.

Corrosion and Weather Protection

When choosing braided brake lines, considering their corrosion and weather protection is essential for guaranteeing durability and reliable performance. High-quality lines with stainless steel braids resist corrosion from road salt, moisture, and debris, preventing deterioration over time. Protective coatings like black vinyl or weather-resistant polymers shield the inner lining from environmental damage, UV rays, and chemical exposure. These features help maintain the integrity of the PTFE or rubber lining, avoiding leaks and performance drops. Proper protection markedly extends the lifespan of brake lines, especially in harsh conditions such as snow, rain, or off-road driving. Investing in lines with durable coatings reduces maintenance needs and ensures consistent braking performance, giving you confidence in your vehicle’s stopping power regardless of the weather.

Cost and Brand Reliability

Choosing the right braided brake lines often comes down to cost and brand reliability, as these factors directly impact safety and longevity. Reputable brands typically offer certified lines that meet or exceed DOT standards, guaranteeing quality and safety. Higher-priced options often feature premium materials like PTFE lining and stainless steel braiding, which boost durability and performance. Established brands usually provide warranties and reliable customer support, giving peace of mind against defective products. On the other hand, cheaper options can sometimes compromise on material strength or quality of fittings, risking safety and performance. By selecting trusted brands with positive reviews, I can be confident in long-term reliability and compliance with safety standards. Investing in reputable lines ultimately saves money and ensures superior stopping power.

Frequently Asked Questions

How Do Braided Brake Lines Improve Stopping Power?

Braided brake lines improve stopping power by providing a more responsive and consistent brake feel. Unlike rubber hoses, they don’t expand under pressure, which means I get better control and less pedal fade during intense braking. This durability also reduces the risk of line failure, ensuring safer, more reliable stops. Overall, braided lines give me confidence that my brakes will perform at their best when I need them most.

Are Braided Brake Lines Compatible With All Vehicle Types?

Think of braided brake lines as the arteries of your vehicle’s braking system, delivering fluid with precision. They’re generally compatible with most vehicle types, but I always recommend double-checking your make and model. Some cars might need adapters or specific sizes. If you’re unsure, consulting your vehicle’s manual or a professional mechanic guarantees you get the perfect fit for reliable, safe stopping power.

What Maintenance Is Required for Braided Brake Lines?

When it comes to maintaining braided brake lines, I check them regularly for signs of wear, cracking, or leaks. I also verify the fittings are tight and free of corrosion. It’s important to keep the brake fluid clean and at proper levels, since contaminated fluid can affect performance. Periodic inspections during routine maintenance help me catch any issues early, ensuring my brake lines stay in top shape and perform reliably.

How Long Do Braided Brake Lines Typically Last?

Braided brake lines are tough, but they don’t last forever. Usually, I’d expect them to serve you well for about 6 to 10 years, depending on driving habits and climate. Regular inspections help catch any wear early. If you notice cracks, leaks, or stiffness, it’s time to replace them—think of it as upgrading your stopping power before disaster strikes. Proper care guarantees they keep you safe mile after mile.

Can Braided Brake Lines Withstand Extreme Weather Conditions?

Braided brake lines are designed to handle extreme weather conditions, and I’ve found they perform well in both hot and cold climates. Their reinforced construction resists expansion and deterioration caused by moisture, salt, and temperature fluctuations. So, whether you’re facing freezing winters or scorching summers, braided lines maintain their integrity and provide consistent braking performance. Just make sure to choose high-quality lines to guarantee durability in severe weather.

Conclusion

When you upgrade to braided brake lines, you’re giving your vehicle a trusty armor shield, ensuring every stop is as smooth as a silk ribbon. Think of it as arming your ride with a lightning-fast reflex, turning braking into a confident dance rather than a nervous stumble. So, choose wisely and let your brakes sing like a well-tuned orchestra, ready to handle any stop in your journey with the power of a storm contained.