During high-load runs, effective thermal management is essential to prevent your battery from overheating and losing performance. You can use active systems like liquid cooling or thermoelectric devices to quickly remove excess heat, while passive methods such as heat sinks, phase change materials, and insulation help stabilize temperatures naturally. Monitoring technologies and advanced control systems fine-tune the process for safety and efficiency. Keep exploring to discover how innovative strategies can optimize your battery’s temperature control.

Key Takeaways

- Active cooling systems like liquid or air-based methods efficiently remove heat generated during high-power demands.

- Real-time temperature monitoring with sensors enables dynamic adjustments to maintain optimal battery temperatures.

- Phase change materials help absorb excess heat during peak loads, preventing thermal runaway and degradation.

- Advanced thermal management integrates predictive algorithms to anticipate and mitigate overheating risks proactively.

- Incorporating thermal insulation and high-conductivity materials ensures even temperature distribution and enhances safety.

Understanding Heat Generation in High-Load Battery Operations

Have you ever wondered why batteries heat up during intense use? When you push a battery to deliver high power quickly, chemical reactions inside accelerate, generating more heat. This increased activity causes ions to move rapidly between electrodes, releasing thermal energy. As current flows at high loads, internal resistance also rises, converting electrical energy into heat. This process isn’t just about faster charging or discharging; it’s a natural consequence of the physics involved. The more demanding the operation, the more heat is produced. If this heat isn’t managed properly, it can lead to performance drops or damage. Understanding how heat is generated helps you appreciate the importance of thermal management systems to keep batteries safe and efficient during high-load conditions. Additionally, thermal conductivity of materials used in battery components plays a crucial role in dispersing heat effectively.

Challenges in Maintaining Optimal Battery Temperatures

Maintaining ideal battery temperatures is a complex challenge because batteries are sensitive to both overheating and excessive cooling, which can impair performance and lifespan. During high-load runs, heat generation increases rapidly, risking thermal runaway or accelerated degradation. Conversely, cooling the battery too much can reduce its efficiency and slow response times. External factors like ambient temperature fluctuations and varying driving conditions also complicate temperature control. Insufficient thermal management can lead to uneven temperature distribution within the pack, causing cell imbalance and reducing overall lifespan. Achieving a precise balance requires constant monitoring and adjustments, making it difficult to maintain suitable conditions consistently. Additionally, thermal management systems must be designed to quickly adapt to changing operating environments, further complicating the process. These challenges demand careful consideration in designing systems capable of adapting quickly to changing operating environments.

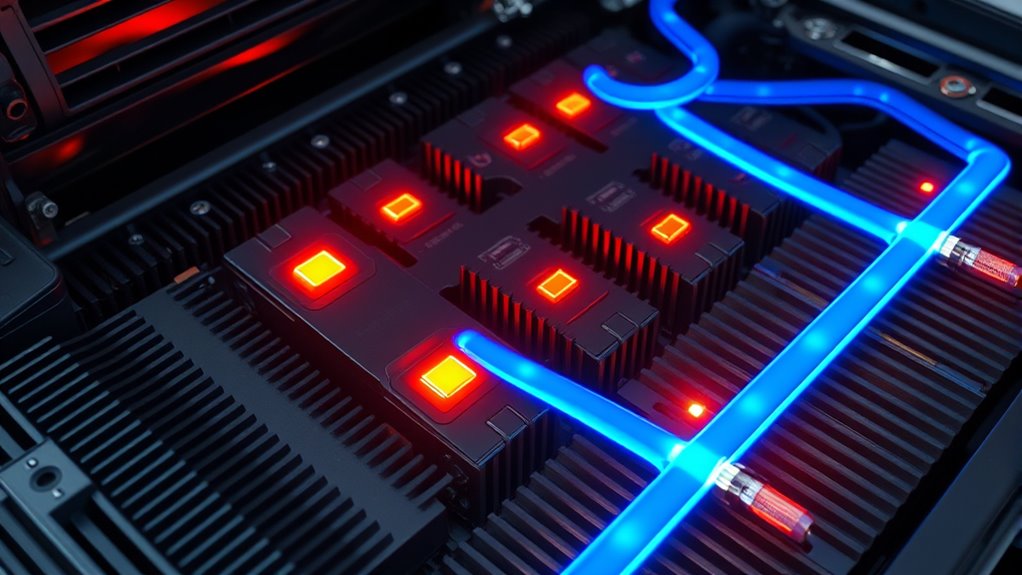

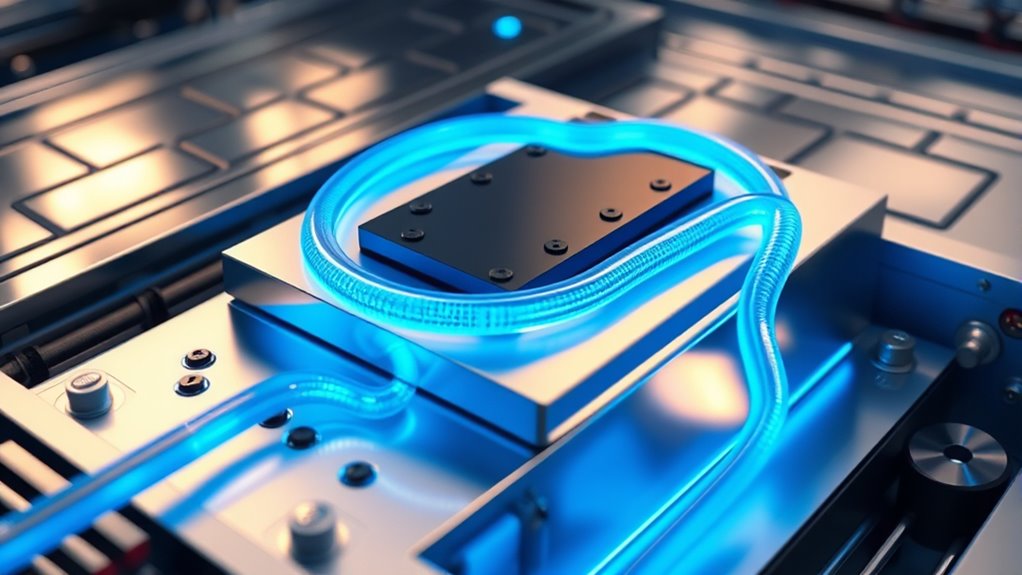

Active Thermal Management Technologies and Systems

Active thermal management systems play an essential role in keeping battery temperatures within ideal ranges by actively controlling heat flow through advanced technologies. You might use liquid cooling, where a coolant circulates through channels near the battery cells to absorb and transfer heat efficiently. Alternatively, air-based systems employ fans or blowers to direct airflow over battery surfaces, removing excess heat. Thermoelectric devices, such as Peltier modules, can also be integrated to either heat or cool specific areas rapidly. These systems often include sensors and control units that monitor temperature in real-time, adjusting cooling or heating as needed. Kia Tuning technologies can also be applied to optimize thermal management strategies, ensuring better performance and longevity for electric vehicle batteries. By actively managing heat, these technologies help prevent overheating during high-load runs, improve performance, and extend battery life.

Passive Cooling Strategies for High-Performance Batteries

Passive cooling strategies are essential for high-performance batteries because they help regulate temperature without relying on external power sources. These methods use natural phenomena like conduction, convection, and radiation to dissipate heat effectively. For example, you can incorporate heat sinks made of thermally conductive materials to draw heat away from cells. Designing battery packs with airflow pathways enhances natural convection, allowing heat to escape efficiently. Using phase change materials can absorb excess heat during high loads, stabilizing temperature spikes. Additionally, embedding batteries in thermal insulating materials can prevent heat buildup. Employing high thermal conductivity materials can further improve heat dissipation. Passive strategies are reliable, maintenance-free, and energy-efficient, making them ideal for long-term operation. They complement active systems and are particularly useful in scenarios where power consumption and complexity need to be minimized.

Future Innovations in Thermal Control and Safety Measures

Innovations in thermal control and safety measures promise to revolutionize battery management by integrating intelligent, adaptive technologies. Future systems will use real-time data to optimize cooling, prevent overheating, and enhance safety during high-load conditions. Smart sensors and machine learning algorithms will predict thermal issues before they occur, allowing proactive adjustments. Advanced materials, such as phase-change composites, will improve heat absorption and dissipation. Safety features like automated shutdowns and fire suppression will become more reliable and faster. Additionally, integrating Mazda Tuning techniques can lead to more efficient thermal management strategies tailored for high-performance applications. Here’s a glimpse of upcoming innovations:

| Technology | Function | Benefit |

|---|---|---|

| Smart Sensors | Monitor temperature and current | Prevent overheating |

| Machine Learning Algorithms | Predict thermal events | Reduce failure risks |

| Phase-Change Materials | Absorb and release heat | Maintain stable temperature |

| Automated Safety Systems | Trigger shutdowns or cooling responses | Minimize hazards |

| Thermal Management Software | Optimize cooling strategies | Enhance efficiency |

Frequently Asked Questions

How Does Ambient Temperature Affect Battery Thermal Management During High Loads?

Ambient temperature directly impacts your battery’s thermal management during high loads. Hot temperatures make it harder for your system to keep the battery cool, increasing the risk of overheating and damage. Conversely, cold environments can hinder performance and cause inefficiencies. You need to monitor and adjust cooling systems accordingly, especially in extreme conditions, to maintain ideal battery health and guarantee safe, reliable performance during high-load runs.

What Are the Environmental Impacts of Different Cooling Systems Used in Batteries?

Did you know that cooling systems can reduce battery energy consumption by up to 30%? When you consider environmental impacts, air cooling uses less water but produces more noise and dust, while liquid cooling offers efficient temperature control but consumes more resources to manufacture. You should weigh these factors, as choosing a sustainable cooling system helps lower your carbon footprint and preserves natural resources.

How Do Thermal Management Strategies Vary Between Electric Vehicle and Grid Storage Applications?

You’ll notice that thermal management strategies differ between electric vehicles and grid storage. In EVs, you prioritize quick heat dissipation to prevent overheating during high loads, often using liquid cooling or phase change materials. For grid storage, you focus on maintaining stable temperatures over longer periods with passive cooling or simple air systems. These tailored approaches guarantee safety, efficiency, and longevity for each application’s specific demands.

What Maintenance Practices Are Recommended for Thermal Management Systems?

You should regularly inspect your thermal management system for leaks, corrosion, and worn components. Keep cooling fans, pumps, and heat exchangers clean and free of debris to guarantee efficient heat transfer. Check fluid levels and replace thermal fluids according to manufacturer guidelines. Monitor system performance with diagnostic tools, and schedule professional maintenance periodically to prevent overheating and ensure ideal operation during high-load conditions.

Are There Any New Materials Improving Heat Dissipation in Batteries?

You’re wondering if new materials are enhancing heat dissipation in batteries. Researchers are developing advanced thermal interface materials and phase change materials that improve heat transfer and stability. These innovations help keep batteries cooler during demanding use, boosting performance and lifespan. By adopting these cutting-edge materials, you can guarantee your battery operates efficiently under high loads, reducing overheating risks and maintaining ideal thermal management during intense high-load runs.

Conclusion

Managing battery heat during high loads is like steering a ship through turbulent waters—you need steady hands and smart tools. Active and passive strategies work together to keep temperatures in check, ensuring safety and performance. As technology advances, expect innovations that act as a protective shield, turning thermal challenges into stepping stones. By mastering thermal management, you not only extend battery life but also navigate toward a safer, more reliable energy future.