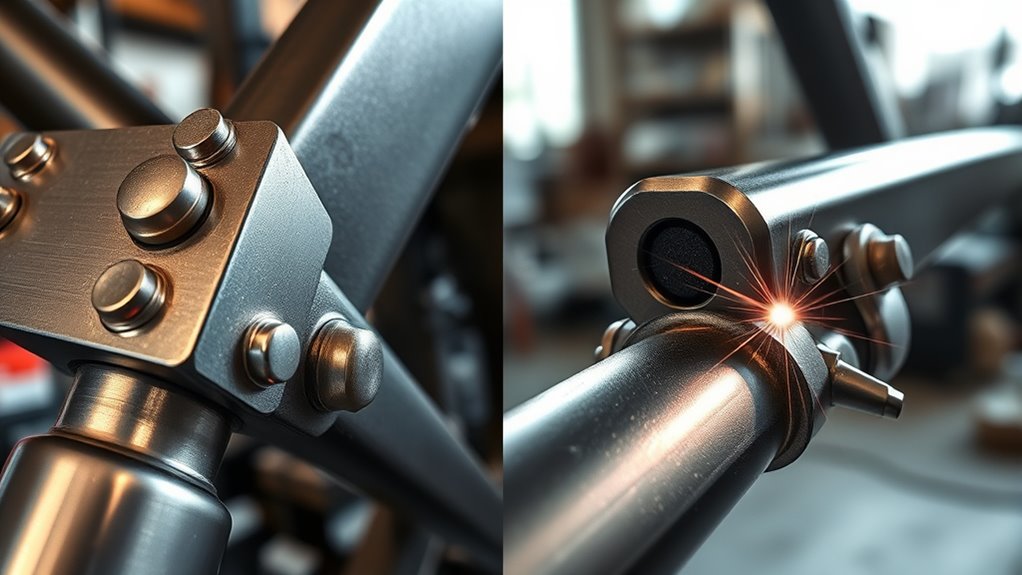

When choosing between riveting and welding for KTM frame builds, consider that riveting offers flexibility, easier repairs, and preserves material strength through fast, efficient assembly–ideal for complex shapes and lightweight designs. Welding creates a rigid, seamless, and highly durable frame, suitable for high-performance needs and large-scale manufacturing. Both methods have their advantages, so understanding their differences can help you decide which is best for your motorcycle’s design and performance. Keep going to explore more details.

Key Takeaways

- Riveting provides flexible, high-strength joints suitable for complex KTM frames and easier repairs, while welding offers rigid, monolithic structures for durability.

- Riveting allows faster assembly and preserves material integrity without thermal distortion, unlike welding, which involves high heat.

- Welding creates seamless, lightweight, and highly durable frames ideal for high-volume manufacturing, whereas riveting is better for complex shapes.

- Riveting facilitates modifications and repairs due to removable fasteners, while welding results in permanent joints with greater structural rigidity.

- Choice depends on performance needs: riveting emphasizes flexibility and ease of assembly, welding focuses on strength and streamlined design.

Have you ever wondered how motorcycle frames are constructed and what methods guarantee their durability? When it comes to building a KTM frame, two primary techniques stand out: riveting and welding. Both methods have their advantages and are chosen based on the desired balance of strength, manufacturing efficiency, and overall performance. Understanding how each process affects material strength and production speed can help you appreciate why manufacturers select one over the other.

Riveting involves joining frame components with metal fasteners, typically rivets, that are driven through pre-drilled holes. This method maintains high material strength because it distributes load evenly across the connection points, reducing stress concentrations that can lead to cracks or failures. Riveted joints also allow for some flexibility, which can absorb shocks better and improve the frame’s resilience during aggressive riding conditions. From a manufacturing perspective, riveting can be more efficient in certain scenarios, especially when working with complex shapes or lightweight materials. It doesn’t require the high heat of welding, which means less thermal distortion and a cleaner process overall. This can translate into faster assembly times, reducing production costs and enabling quicker turnaround times.

Riveting provides strong, flexible joints with efficient, low-heat assembly suited for complex lightweight KTM frames.

On the other hand, welding involves fusing metal parts together through high heat, creating a continuous, solid joint. This method often results in a very rigid connection, which can enhance the overall structural integrity of the frame. Welding typically produces a stronger joint in terms of pure material strength, especially when performed correctly, as it eliminates the need for additional fasteners and reduces weight. However, welding requires precise control of heat input; poor welding can introduce weaknesses due to thermal stresses or incomplete fusion. For KTM frames, the choice of welding can boost manufacturing efficiency when producing high-volume runs because it allows for automated processes that ensure consistent, high-quality joints. Plus, welded frames tend to be more streamlined, which can improve aerodynamics and aesthetics.

Additionally, advances in welding technology have made it possible to produce joints with even greater strength and precision, further influencing the decision-making process in frame construction. Ultimately, the decision between riveting and welding hinges on the specific performance requirements and production goals. Riveting offers a flexible, efficient solution that preserves material strength and allows for easier repairs or modifications. Welding, however, provides a monolithic, highly durable structure that can be produced quickly at scale. As a rider, knowing that KTM employs these methods with careful consideration means you’re getting a frame designed for both durability and manufacturing excellence. Whether riveted or welded, the goal remains the same: creating a resilient, high-performance frame that can withstand the demands of aggressive riding while optimizing production efficiency.

Frequently Asked Questions

How Does Riveting Affect Frame Maintenance?

Riveting can make frame maintenance simpler because it allows for easier disassembly and inspection, which helps maintain frame durability over time. However, it may require more frequent checks for loose rivets or corrosion, increasing maintenance complexity. Unlike welding, riveting doesn’t alter the frame’s integrity permanently, so you can replace or repair parts more conveniently, ensuring your bike stays in top condition with less hassle.

Are Welded Frames More Eco-Friendly Than Riveted Ones?

Imagine a frame as a river of metal flowing into the future. Welded frames often seem more eco-friendly because they tend to use fewer materials and have better recycling benefits. They also allow for greater material flexibility, reducing waste. While riveting creates strong bonds, welding’s seamless joins minimize environmental impact. So, in your quest for sustainability, welded frames can be a greener choice, helping you build a more eco-conscious ride.

Which Method Offers Better Vibration Absorption?

Welding generally offers better vibration absorption than riveting because it creates a more rigid connection, improving frame flexibility and vibration damping. This rigidity helps in reducing unwanted vibrations, providing a smoother ride. Riveted frames tend to allow more movement at joints, which can increase vibrations. So, if you prioritize vibration damping and frame flexibility, welding is the better choice for minimizing vibrations and enhancing overall comfort during rides.

Can Riveted Frames Be Repaired Easily?

Riveted frames are generally easier to repair than welded ones, with about 80% of riveted joints being accessible for maintenance. You’ll find that their repair complexity is lower because rivets can often be replaced without extensive disassembly. While riveted frames might slightly compromise overall frame durability, their repair process remains straightforward, making them an appealing choice for those prioritizing easy fixes and long-term durability.

How Do Costs Compare Between Riveting and Welding?

You’ll find that riveting tends to be more cost-efficient for small-scale or repair work, as it involves less manufacturing complexity and requires simpler tools. Welding, on the other hand, often has higher initial costs due to specialized equipment and skilled labor, but it can be cheaper for large-scale production because it offers stronger joints and faster assembly. Overall, your choice depends on balancing initial expenses with long-term durability.

Conclusion

Ultimately, whether you choose riveting or welding, think of your frame as the heartbeat of your ride. Riveting symbolizes the strength of connection, like bonds that withstand time, while welding embodies seamless unity, a fusion of precision. Each method tells a story—one of resilience, one of craftsmanship. Your decision shapes not just the frame, but the soul of your KTM. So, pick the path that resonates with your spirit and ride with confidence, knowing your choice is part of your journey.