Choosing between carbon fiber, aluminum, and steel depends on your project’s structural needs, durability, and sustainability goals. Carbon fiber offers high strength-to-weight ratio but at a higher cost and sensitivity to impact. Aluminum is lightweight and versatile—ideal for complex shapes and aesthetics—while steel provides proven strength, durability, and cost-efficiency for large-scale or load-bearing structures. Understanding each material’s performance and application nuances can help match your design ambitions with suitable choices. Exploring these aspects reveals how each material can shape innovative architectural solutions.

Key Takeaways

- Carbon fiber offers high strength-to-weight ratio but is costly and brittle, suited for high-performance, specialized architectural components.

- Aluminum is lightweight, versatile, and supports complex designs with good aesthetic appeal, ideal for innovative facades and intricate forms.

- Steel provides superior load-bearing capacity, durability, and flexibility, making it suitable for large-scale, resilient structures.

- Cost, sustainability, and ease of fabrication influence material selection, with steel being most economical and recycled, aluminum offering recyclability, and carbon fiber being high-performance but expensive.

- Future trends favor sustainable, smart, and recyclable materials, emphasizing lifecycle impact and advanced manufacturing techniques in architectural design.

What Are the Strengths and Weaknesses of Carbon Fiber in Architecture?

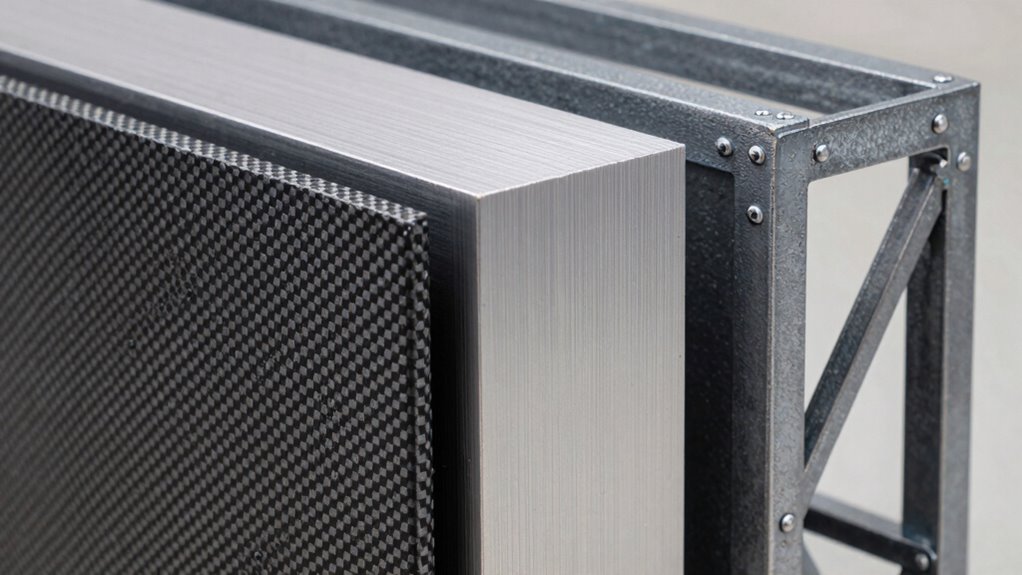

Carbon fiber offers several compelling advantages for architectural applications due to its exceptional strength-to-weight ratio and high stiffness. Its high tensile strength allows you to create slender, elegant structures with reduced material volume, enabling innovative designs that were previously unfeasible. Additionally, carbon fiber exhibits excellent fatigue resistance and dimensional stability, ensuring long-term durability under dynamic loads. Research-driven insights can guide effective material selection and application strategies, helping you optimize design outcomes. Its versatility in material applications contributes to a broader range of architectural possibilities, especially in complex or lightweight structures. Moreover, ongoing advances in manufacturing techniques are gradually reducing production costs, making the material more accessible for diverse projects. The development of cost-effective production methods is also expanding the potential for wider adoption in the architectural field. Furthermore, improvements in manufacturing consistency are enhancing the reliability and quality of carbon fiber components. However, you must consider its significant weaknesses. Its high production cost limits widespread use, and the material’s brittleness can lead to sudden failure without warning. Handling and fabrication require specialized skills and equipment, which can complicate construction processes. Furthermore, carbon fiber’s susceptibility to UV degradation necessitates protective coatings for outdoor applications. Understanding these strengths and weaknesses helps you evaluate its suitability for specific architectural projects.

Why Is Aluminum a Favorite for Lightweight, High-Performance Buildings?

Aluminum’s lightweight nature considerably reduces structural load, enabling efficient high-performance designs. Its excellent corrosion resistance minimizes maintenance and extends lifespan, ensuring durability in various environments. Additionally, aluminum offers extensive design flexibility, allowing architects to achieve complex forms without compromising strength or weight. Its recyclability also contributes to sustainable construction practices, making it a favored choice in lifestyle products for innovative and durable building solutions. Furthermore, aluminum’s thermal conductivity enhances energy efficiency in building applications, providing additional functional benefits. Moreover, aluminum’s versatility is evidenced by its widespread use in automotive and aerospace industries, demonstrating its adaptability across different fields.

Lightweight Structural Advantage

Because of its exceptional strength-to-weight ratio, aluminum is a preferred choice for lightweight, high-performance building structures. This characteristic reduces overall load on foundations and support systems, enabling innovative architectural designs. Aluminum’s high specific strength allows for slender, efficient frameworks that maximize interior space without compromising stability. Its ease of fabrication facilitates rapid assembly and adaptability during construction. Additionally, aluminum’s ductility enhances structural resilience under dynamic loads, such as wind or seismic forces. Its low density minimizes transportation costs and simplifies handling on-site. These properties collectively contribute to improved structural efficiency, reduced construction time, and increased design flexibility. Moreover, aluminum’s corrosion resistance ensures longevity and low maintenance for building exteriors, further enhancing its appeal in various environments. This corrosion resistance is especially beneficial in coastal or harsh climates, where durability is crucial. The recyclability of aluminum also supports sustainable building practices by reducing environmental impact. Furthermore, advancements in aluminum treatment techniques have improved its resistance to environmental degradation, extending the lifespan of structures. Additionally, the development of eco-friendly fabrication methods has made aluminum a more sustainable choice for modern construction projects.

Corrosion Resistance Benefits

Corrosion resistance is a critical factor that makes aluminum an ideal material for lightweight, high-performance building applications. Aluminum naturally forms a thin oxide layer when exposed to air, providing a durable barrier against environmental elements. This passive layer inhibits oxidation and prevents deterioration caused by moisture, chlorides, and pollutants. Unlike steel, aluminum does not require frequent maintenance or protective coatings to maintain its integrity over time. Its corrosion resistance guarantees long-term structural stability and aesthetic appeal, reducing lifecycle costs. Additionally, aluminum’s resistance extends to various environments, including coastal and industrial settings, where corrosive agents are prevalent. This inherent durability allows you to design with confidence, knowing that aluminum will maintain its performance and appearance without extensive treatment or repair. Understanding material properties helps in selecting the right material for specific environmental challenges, such as corrosion resistance, which is essential for sustainable construction. Recognizing the environmental durability of aluminum helps ensure that buildings remain resilient and require fewer repairs over their lifespan. Moreover, advancements in corrosion-resistant alloys continue to enhance aluminum’s suitability for even more demanding conditions.

Design Flexibility Options

Aluminum offers exceptional design flexibility, making it a preferred choice for lightweight, high-performance buildings. Its malleability enables complex geometries and intricate facades, facilitating innovative architectural expressions. You can easily incorporate custom profiles and thin-walled structures without compromising strength or stability. The material’s high strength-to-weight ratio allows for larger spans and open spaces, reducing structural mass. Its compatibility with advanced fabrication techniques, such as CNC machining and extrusion, ensures precision in manufacturing. Additionally, aluminum’s surface treatment options—anodizing, coating, and polishing—enhance aesthetic versatility and durability. This adaptability simplifies integration with other materials and systems, streamlining construction workflows. Moreover, aluminum’s recyclability contributes to sustainable building practices. Understanding the material properties of aluminum helps architects optimize performance and longevity in their designs. Its corrosion resistance further extends its suitability for diverse environments, ensuring long-term durability and reduced maintenance. Recognizing aluminum’s lightweight nature can also lead to reductions in transportation and installation costs, benefiting overall project budgets. Aluminum’s ability to be easily fabricated into complex shapes further broadens its application scope, enabling innovative structural solutions. Overall, aluminum’s versatility empowers architects and engineers to push creative boundaries while meeting structural and performance requirements efficiently.

How Does Steel Ensure Structural Stability and Longevity?

Steel’s inherent strength and ductility make it an ideal material for maintaining structural stability and guaranteeing long-term durability in arch-level constructions. Its high tensile and compressive resistance allow it to withstand significant loads without deformation or failure. The material’s ductility ensures it can absorb energy during dynamic events, such as seismic activity, reducing the risk of catastrophic collapse. Steel’s resilience to fatigue and fracture contributes to its longevity, even under cyclical stress. Corrosion-resistant treatments and protective coatings further extend its lifespan, preventing deterioration over decades. Precise engineering of steel components ensures load distribution remains ideal, maintaining the integrity of complex arches and supports. Consequently, steel delivers consistent performance, supporting stability and durability essential for the safety and longevity of arch-level structures.

How Do Carbon Fiber, Aluminum, and Steel Compare in Strength, Weight, and Flexibility?

Understanding how carbon fiber, aluminum, and steel compare involves examining their material strength and durability, which directly affect load-bearing capacity. You also need to take into account weight and performance trade-offs, as lighter materials can enhance efficiency but may compromise rigidity. Ultimately, flexibility influences design options, enabling tailored structural solutions based on specific architectural requirements.

Material Strength and Durability

When evaluating materials for arch-level construction, it’s essential to contemplate their strength, weight, and flexibility, as these properties directly influence structural performance and safety. Carbon fiber offers exceptional tensile strength and high durability but can be brittle under impact. Aluminum provides a good balance of strength and corrosion resistance, though it’s less durable than steel. Steel exhibits superior compressive and tensile strength with proven long-term durability, but it is heavier and more prone to corrosion without treatment.

- Carbon fiber resists fatigue and environmental degradation

- Aluminum’s strength-to-weight ratio is high but less impact-resistant

- Steel withstands high loads with proven durability

- Carbon fiber’s brittleness can lead to sudden failure

- Aluminum requires protective coatings to prevent corrosion

Weight and Performance Trade-offs

Choosing the most suitable material for arch-level construction involves carefully balancing strength, weight, and flexibility to guarantee structural integrity and efficiency. Carbon fiber offers exceptional strength-to-weight ratios, reducing overall mass without sacrificing load capacity, but its rigidity limits flexibility. Aluminum provides a favorable balance with moderate strength and considerably lighter weight than steel, enabling easier handling and installation, though it may require thicker sections for comparable strength. Steel remains the heaviest option but excels in tensile strength and ductility, allowing for greater flexibility under dynamic loads. These trade-offs influence performance: carbon fiber maximizes lightweight design, aluminum enhances ease of assembly, and steel ensures durability under variable conditions. Selecting the ideal material hinges on specific structural demands and performance priorities.

Flexibility and Design Options

Among the three materials, carbon fiber offers the highest stiffness and strength-to-weight ratio but exhibits limited flexibility, making it ideal for applications where rigidity is paramount. Aluminum provides moderate flexibility and can be shaped into complex forms, supporting innovative design options. Steel, while less flexible than aluminum, offers significant strength and ductility, enabling structural resilience and deformation under stress.

- Carbon fiber’s rigidity limits its ability to absorb impacts but allows for precise, lightweight structural components.

- Aluminum’s flexibility facilitates intricate shaping and adaptive designs, supporting custom architectural features.

- Steel’s ductility permits complex, load-bearing structures with enhanced durability.

- Carbon fiber’s limited flexibility constrains certain architectural forms but excels in high-performance applications.

- Aluminum and steel offer greater design versatility in terms of bending and forming, accommodating diverse architectural aesthetics.

What Are the Costs of Using Carbon Fiber, Aluminum, and Steel?

The costs associated with using carbon fiber, aluminum, and steel vary considerably based on material properties and manufacturing processes. Carbon fiber offers high strength-to-weight ratios but incurs significant expenses due to complex fabrication, raw material costs, and specialized labor. Aluminum presents a moderate cost profile, combining ease of fabrication with lower weight, but still demands higher prices than steel. Steel remains the most economical option, benefiting from mature manufacturing techniques and abundant raw materials, though it involves heavier weight and potential long-term maintenance costs. These financial considerations directly influence project budgets, with carbon fiber typically increasing initial investment, aluminum offering a balance of performance and cost, and steel providing the most cost-effective solution for large-scale or budget-constrained builds.

How Sustainable Are These Materials for Eco-Friendly Building Designs?

The sustainability of carbon fiber, aluminum, and steel in eco-friendly building designs depends largely on their production, lifecycle impacts, and recyclability. You must consider the energy consumption during manufacturing, the durability over the building’s lifespan, and how efficiently these materials can be recycled.

- Carbon fiber requires high-energy production, but offers longevity and lightweight benefits for reduced structural loads.

- Aluminum’s recycling process consumes considerably less energy than primary production, making it highly recyclable.

- Steel has a well-established recycling infrastructure, with over 90% of steel recycled, lowering its environmental footprint.

- Lifecycle impacts vary based on sourcing, manufacturing practices, and end-of-life disposal.

- Material selection should prioritize low-impact extraction, energy-efficient processing, and high recyclability to enhance sustainability.

Where Are Carbon Fiber, Aluminum, and Steel Best Used in Architecture?

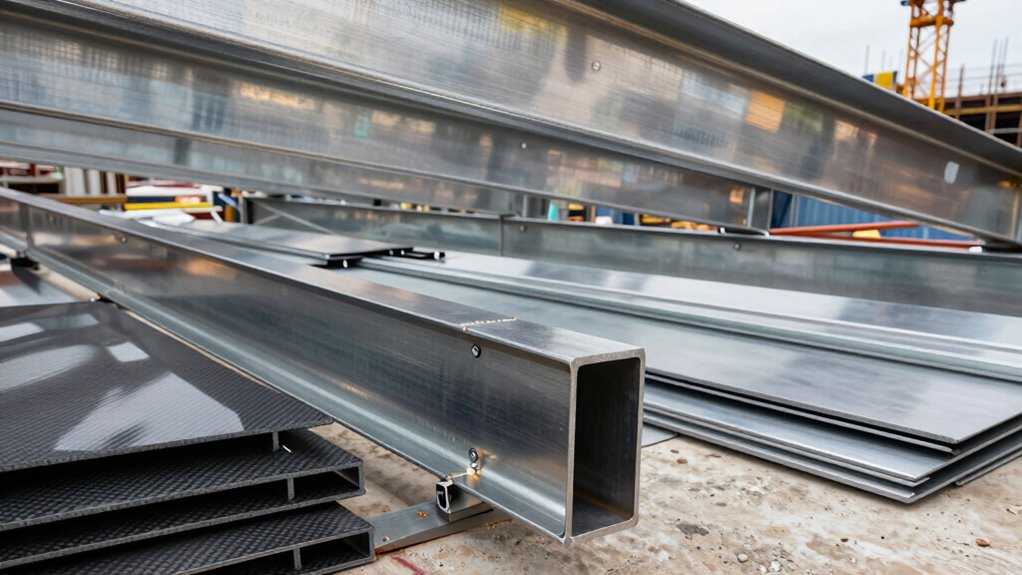

Carbon fiber excels in applications requiring high strength-to-weight ratios, such as long-span roof structures and slender facades, where reduced structural load is critical. Its exceptional tensile strength and low density allow for innovative, lightweight designs that maximize spatial efficiency. Aluminum performs best in façades, window frames, and curtain walls due to its corrosion resistance, ease of fabrication, and favorable strength-to-weight ratio. It enables complex, aesthetically appealing forms with streamlined installation. Steel remains the material of choice for load-bearing frameworks, bridges, and structural reinforcements, given its superior ductility, high yield strength, and cost-effectiveness. Steel’s proven durability under dynamic loads and its well-established construction techniques make it indispensable in critical structural components. Each material’s *ideal* application depends on balancing performance requirements, structural demands, and design objectives.

What Are the Installation Challenges and Maintenance Needs of Each Material?

You need to take into account how installation complexities differ among materials, affecting project timelines and labor requirements. Long-term maintenance demands vary, with some materials requiring specialized upkeep to preserve structural integrity. Understanding these challenges ensures informed material selection aligned with your project’s durability and cost considerations.

Installation Complexity Variations

Installation challenges and maintenance requirements vary considerably among materials used in arch-level construction, directly impacting project timelines and long-term performance. Carbon fiber demands specialized handling and precise bonding procedures, complicating installation. Aluminum requires careful surface preparation and precise fastening techniques to prevent galvanic corrosion. Steel installation involves extensive welding, structural anchoring, and alignment, increasing complexity. Each material’s installation process influences labor, time, and quality control.

- Carbon fiber necessitates advanced bonding techniques

- Aluminum demands detailed surface treatments

- Steel involves complex welding and structural alignment

- Material-specific tools are essential for proper installation

- Precise handling minimizes long-term durability issues

Long-term Maintenance Demands

While each material used in arch-level construction presents unique installation challenges, their long-term maintenance demands vary considerably. Carbon fiber requires minimal upkeep due to its corrosion resistance, but periodic inspections ensure structural integrity. Aluminum demands regular cleaning to prevent oxidation, which can compromise appearance and performance. Steel necessitates ongoing anti-corrosion treatments, such as painting or galvanizing, to prevent rust.

| Material | Maintenance Needs |

|---|---|

| Carbon | Minimal; periodic structural inspections |

| Aluminum | Cleaning; oxidation prevention |

| Steel | Corrosion protection; repainting or galvanizing |

Understanding these demands helps you plan for lifecycle costs, ensuring durability and safety over time. Proper maintenance extends material lifespan, preserving structural integrity and aesthetic quality.

How Do You Choose the Right Material for Your Architectural Project?

Selecting the appropriate material for an architectural project requires a systematic evaluation of multiple factors, including structural requirements, environmental conditions, aesthetic goals, and budget constraints. You must align material properties with project specifications to guarantee performance and longevity. Consider the material’s strength-to-weight ratio, corrosion resistance, and thermal insulation. Analyze lifecycle costs and maintenance needs to optimize long-term value. Additionally, assess environmental impact and sustainability credentials. Your choice should also reflect the desired aesthetic and compatibility with other materials.

Choosing the right material involves balancing performance, durability, cost, and sustainability for lasting architectural success.

- Structural load-bearing capacity

- Environmental durability

- Cost-effectiveness over time

- Aesthetic compatibility

- Sustainability and eco-friendliness

What Are the Future Trends Shaping Architectural Materials?

Emerging technological advancements and growing environmental concerns are driving significant shifts in architectural materials. You’ll see increased integration of smart materials that adapt to environmental conditions, such as self-healing concrete and thermochromic glass. Sustainable options like recycled metals, bio-based composites, and carbon-neutral alternatives are gaining prominence, reducing the carbon footprint of construction projects. Additive manufacturing techniques enable complex geometries with minimal waste, while nanotechnology enhances material strength and durability. Digital fabrication tools foster precision and customization, aligning with the trend toward modular construction. Additionally, lifecycle analysis informs material selection, emphasizing longevity and recyclability. As these trends evolve, you’ll need to stay informed about innovations that optimize structural performance, environmental impact, and cost-efficiency in architectural design.

Frequently Asked Questions

How Do Environmental Impacts Differ Among Carbon Fiber, Aluminum, and Steel?

You’ll find that carbon fiber has the lowest environmental impact during production due to its lightweight nature, reducing transportation emissions. Aluminum’s extraction is energy-intensive, contributing considerably to carbon emissions, but it’s highly recyclable, which mitigates long-term impacts. Steel has the highest initial environmental footprint because of its energy-heavy manufacturing, yet its recyclability is excellent. Overall, aluminum and steel have higher embodied energy than carbon fiber, which offers a more sustainable option if recycling is prioritized.

What Are the Fire Resistance Properties of Each Material?

You’ll find that steel offers excellent fire resistance, as it maintains strength and integrity longer at high temperatures, though it can weaken if exposed to extreme heat. Aluminum has lower fire resistance; it melts at around 660°C, risking structural failure. Carbon fiber, being combustible, has poor fire resistance unless specially treated with fire-retardant coatings. Proper fireproofing measures are essential for all materials to guarantee safety.

Can These Materials Be Recycled or Reused Effectively?

You can recycle steel and aluminum efficiently; steel is highly recyclable with minimal quality loss, and aluminum can be melted down repeatedly. Carbon fiber, however, poses challenges due to complex recycling processes, often resulting in downcycling rather than true reuse. Proper recycling depends on material purity and processing capabilities. When selecting materials, consider their recyclability to enhance sustainability and reduce environmental impact in architectural projects.

How Do Climate Conditions Influence Material Selection?

Climate conditions subtly steer your material choices, as they directly affect durability and performance. In humid environments, you’ll prefer corrosion-resistant options like aluminum or treated steel, while cold regions demand materials that withstand thermal contraction. Wind and seismic zones require flexibility and strength, favoring steel or composite materials. By analyzing local climate factors precisely, you guarantee your structure’s longevity, safety, and efficiency, optimizing material performance in every environmental context.

What Are the Long-Term Performance Expectations for Each Material?

You can expect carbon fiber to maintain its high strength-to-weight ratio and resist fatigue over time, making it ideal for demanding applications. Aluminum offers excellent corrosion resistance and moderate durability, but it may require maintenance to prevent degradation. Steel provides exceptional long-term strength and durability, especially in structural elements, but it’s prone to corrosion if not properly protected. Your choice depends on balancing these long-term performance factors with your project’s specific needs.

Conclusion

Choosing the ideal material hinges on balancing strength, weight, cost, and application. Carbon fiber, aluminum, and steel each excel in different areas, akin to players on a team, each with a unique role. By understanding their properties and challenges, you can craft structures that stand the test of time and innovation. Ultimately, selecting the right material isn’t just a choice—it’s the foundation upon which your architectural vision becomes reality.