On slow trails, your bike overheats mainly because low airflow and prolonged low-RPM operation prevent effective cooling, causing heat to build up. Friction from worn components like brake pads, chain, or sprockets adds to the temperature rise, especially under increased terrain resistance or mud. Poor maintenance and inadequate lubrication further exacerbate heat. To prevent this, optimizing airflow, maintaining components, and adjusting riding habits are vital—continue if you want to uncover deeper insights into controlling engine temperatures during slow rides.

Key Takeaways

- Reduced airflow during slow riding limits natural cooling of the radiator and engine components.

- Extended low RPM operation causes heat buildup due to insufficient airflow and stagnant coolant circulation.

- Mechanical issues like clogged radiators, malfunctioning fans, or worn cooling parts impair heat dissipation.

- Trail conditions such as mud, rocks, or uphill climbs increase engine load, raising operating temperature.

- Inadequate maintenance, including dirty cooling fins and low coolant levels, diminishes the cooling system’s effectiveness.

What Causes Bikes to Overheat During Slow Rides?

When riding at low speeds, your bike’s cooling system becomes less effective because there’s insufficient airflow over the radiator or cooling fins to dissipate heat efficiently. This reduced airflow limits convective heat transfer, causing the coolant temperature to rise. The radiator relies on dynamic airflow to carry away heat absorbed from the engine, but at slow speeds, natural airflow diminishes markedly. Additionally, the fan may not generate enough airflow to compensate, especially if it’s malfunctioning or improperly maintained. This stagnation prevents ideal heat exchange, leading to a buildup of heat within the cooling system. As a result, engine components operate at higher temperatures, increasing the risk of overheating. Proper airflow management and cooling system maintenance are essential to mitigate this issue during slow or stop-and-go riding conditions. Ensuring your cooling system has adequate airflow can significantly improve heat dissipation during these situations. Regular inspection of the cooling fans and ensuring unobstructed airflow paths help maintain optimal cooling performance. Moreover, coolant levels should be checked regularly, as low coolant can further impair heat transfer efficiency. To further enhance cooling, consider upgrading cooling components or adding auxiliary fans to support airflow at low speeds. Additionally, using thermal management techniques such as installing heat shields can help regulate engine temperature during sluggish rides.

How Friction Between Parts Leads to Excess Heat

Friction between bike components converts kinetic energy into heat, raising temperatures during operation. Worn brake pads increase frictional force, generating excess heat in the braking system, while chain and sprocket wear cause increased resistance, leading to greater heat buildup. Additionally, bearing resistance rises with wear and contamination, further amplifying heat generation across moving parts. Regular lubrication and maintenance can reduce friction and help prevent overheating. Incorporating auditory feedback therapy techniques can help in diagnosing unusual noises that may indicate excessive heat or wear issues. Monitoring component wear levels regularly is essential to prevent overheating and ensure optimal performance, especially as material degradation can accelerate heat buildup over time.

Brake Pad Friction

As you brake, the brake pads press tightly against the rotor, creating a significant amount of friction that converts kinetic energy into heat. This friction causes localized high temperatures, which can lead to brake fade or rotor deformation if sustained. The intensity of this heat depends on several factors:

- Pad Material: Higher friction compounds generate more heat but may wear faster.

- Brake Application Force: Greater force increases pressure, elevating temperature.

- Duration of Braking: Longer stops produce more heat accumulation.

- Pad-Rotor Contact Area: Larger contact distributes heat but can also intensify heat transfer. Additionally, the friction process itself directly influences how quickly heat builds up during prolonged or repeated braking. Understanding the material properties of brake pads can help manage heat generation and improve braking performance, especially considering thermal conductivity to dissipate heat more effectively. Maintaining proper brake system maintenance can also prevent excessive heat buildup and ensure consistent braking response.

Chain and Sprocket Wear

Continuous operation of the chain and sprockets causes metal-to-metal contact that generates heat through friction. As your chain wears, the surfaces become uneven, increasing resistance and accelerating heat buildup. Worn sprockets develop sharp or hooked teeth, which cause increased sliding and grinding against the chain links. This elevated friction leads to localized hotspots, weakening the metal over time and causing further wear. When parts aren’t properly lubricated, friction rises exponentially, intensifying heat production. Excessive wear also results in misalignment between the chain and sprocket teeth, creating additional shear forces that generate more heat. Over time, this cycle of increased friction and wear can notably elevate component temperatures, contributing to overall overheating issues during slow or prolonged riding conditions. Additionally, component wear can be linked to the overall health of your bike’s drivetrain, emphasizing the need for regular maintenance. Proper drivetrain maintenance ensures smoother operation and reduces heat buildup. Regular inspection of metal fatigue can help identify early signs of wear before overheating becomes a problem. Recognizing the signs of wear and tear early can help prevent costly repairs and keep your bike running efficiently.

Bearing Resistance Increase

When bearing resistance increases, the internal friction between moving parts intensifies, directly elevating heat levels within the drivetrain. This heightened friction causes components to work harder, generating more heat and risking overheating. The consequences include:

- Accelerated bearing wear, leading to potential failure.

- Increased energy loss, reducing pedaling efficiency.

- Higher temperatures that can degrade lubrication, compounding friction.

- Elevated risk of bearing seizing, which can cause catastrophic drivetrain damage.

These issues stem from contamination, corrosion, or insufficient lubrication, all of which elevate resistance. As resistance climbs, your bike’s components generate excess heat, especially on slow trails where airflow is limited. Regular maintenance and inspection can help identify and address issues before they cause overheating and further damage. Proper lubrication and component alignment also play crucial roles in minimizing resistance. Friction management techniques are essential for preventing excessive heat buildup in your drivetrain. Addressing bearing resistance is vital to prevent overheating and preserve drivetrain longevity. Proper maintenance can help mitigate these issues and extend the lifespan of your bike’s components. Additionally, understanding how contamination and corrosion contribute to resistance can aid in preventing overheating.

Bike Maintenance Tips to Prevent Overheating

Regularly check your chain lubrication to minimize friction and heat buildup, ensuring smooth power transfer. Monitor brake performance for excessive wear or sticking components that can generate unnecessary heat during operation. Additionally, keep your cooling system free of debris and buildup to maintain ideal heat dissipation and prevent overheating. Using vacuum cleaners with HEPA filters can help keep your bike’s surrounding area clean, reducing dust and debris that might contribute to overheating issues.

Check Chain Lubrication Regularly

Proper chain lubrication is essential for preventing excessive friction that can cause your bike’s components to overheat during rides. Insufficient lubrication increases metal-on-metal contact, leading to heat buildup that strains your drivetrain. To maintain peak performance, regularly check and apply lubricant based on these steps:

- Inspect the chain for dryness or dirt buildup, which impairs lubrication effectiveness.

- Clean the chain thoroughly with a degreaser to remove old lubricant and debris.

- Apply a suitable chain lubricant, ensuring it reaches inner links and rollers evenly.

- Wipe off excess lubricant to prevent dirt attraction, maintaining a smooth, low-friction surface.

Consistent lubrication ensures minimal friction, reducing heat generation and preventing overheating during prolonged slow trail rides. Proper maintenance keeps your drivetrain efficient and durable.

Monitor Brake Performance Closely

Monitoring your brake performance is critical because brake overheating can considerably impair stopping power and lead to component failure. Regularly inspect brake pads for uneven wear, glazing, or contamination, which can increase heat buildup. Guarantee brake calipers and pistons move smoothly without sticking, as friction increases heat accumulation. Check the brake fluid levels and condition if you have hydraulic brakes; low or degraded fluid reduces cooling efficiency. Listen for abnormal noises such as squealing or grinding, indicating excessive heat or pad issues. Use a temperature probe if available to measure rotor or pad temperature during prolonged braking. Promptly address any signs of excessive heat, like discoloration or warping, to prevent further damage. Precise monitoring allows you to maintain ideal braking performance and prevent heat-induced failures.

Keep Cooling System Clean

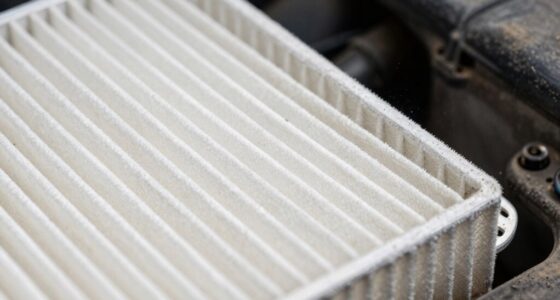

A clean cooling system is essential for maintaining ideal temperature regulation during rides, as accumulated dirt, debris, and grime can obstruct airflow and insulate components, leading to overheating. To guarantee optimal performance, regularly inspect and clean critical parts.

- Remove dirt buildup from the radiator fins to prevent airflow restriction.

- Flush cooling channels to eliminate blockages caused by debris or corrosion.

- Clear dust and grime from cooling fans and vents to sustain effective heat dissipation.

- Check coolant levels and replace coolant periodically, ensuring proper thermal transfer and preventing sludge buildup.

Neglecting these steps can cause thermal inefficiencies, risking engine damage and reduced riding performance. Maintaining a spotless cooling system preserves airflow, enhances heat transfer, and guarantees your bike runs smoothly on slow or challenging trails.

How Your Riding Habits Can Keep Your Bike Cooler

By adjusting your riding habits, you can substantially reduce the heat buildup in your bike’s engine and prevent overheating. Maintain consistent, moderate throttle application instead of rapid acceleration and deceleration, which cause excessive engine strain and heat generation. Choose smoother gear transitions to reduce mechanical friction and avoid abrupt changes that elevate internal temperatures. Incorporate brief, strategic pauses during extended slow riding to allow cooling, especially on inclines or technical sections. Keep RPM levels within manufacturer-recommended ranges to prevent excessive engine stress. Additionally, minimize high-revving during idle or low-speed sections, as sustained high RPMs substantially increase heat. Adopting these disciplined riding techniques helps manage engine load, enhances airflow around vital components, and maintains optimal operating temperatures.

Why Proper Lubrication Helps Prevent Overheating

Proper lubrication is essential for maintaining ideal engine temperatures because it reduces internal friction and wear among moving parts. When lubrication is inadequate, increased friction causes components to generate excessive heat, risking overheating. Ensuring proper lubrication benefits you by:

- Minimizing metal-on-metal contact, preventing heat buildup.

- Reducing mechanical resistance, allowing smoother operation.

- Dissipating heat more effectively, lowering overall engine temperature.

- Extending component lifespan, avoiding costly repairs and breakdowns.

Maintaining peak lubrication levels and using the correct oil type ensures consistent film thickness, which is critical for heat transfer and friction reduction. Proper lubrication not only preserves engine integrity but also enhances performance, especially during slow, prolonged trail rides where heat dissipation challenges are more pronounced.

How Trail Conditions and Terrain Contribute to Overheating

Rough trail conditions and challenging terrain considerably influence your bike’s tendency to overheat, as they force the engine to work harder and generate more heat. Uphill climbs, loose gravel, and uneven surfaces increase drivetrain resistance and require greater power output. These conditions elevate engine RPMs and friction, reducing cooling efficiency. To understand this impact, consider the following factors:

| Terrain Type | Effect on Overheating | Mechanical Demands |

|---|---|---|

| Steep Inclines | Increased engine load, higher temps | Greater clutch and transmission stress |

| Loose Gravel | Reduced traction, higher engine effort | Increased slip and heat generation |

| Rocky Terrain | Vibration and shock increases wear | Elevated lubrication needs |

| Muddy Trails | Resistance from moisture, clogging | Overworking cooling systems |

| Flat, Slow Trails | Low airflow, engine remains hot | Reduced heat dissipation |

Signs of Overheating and How to Cool Your Bike

When your bike starts to overheat, it often shows clear physical and operational signs that demand immediate attention. Recognizing these signs can prevent damage and assure safety. First, you may notice the engine or components emitting a strong, acrid smell, indicating excessive heat. Second, the temperature gauge (if available) will spike sharply, signaling critical levels. Third, you might observe abnormal vibrations or sluggish response, reflecting thermal expansion affecting parts. Fourth, coolant or oil leaks can appear, confirming overheating issues. To cool your bike quickly, turn off the engine, allow it to rest in a shaded area, and carefully inspect and top off coolant or oil if needed. Using a fan or spray of water on the radiator can aid heat dissipation without risking damage.

Top Tips to Prevent Bike Overheating on Slow Trails

To prevent your bike from overheating on slow trails, it’s essential to monitor engine load and manage your riding pace carefully. Reduce throttle engagement during low-speed sections to minimize strain on the cooling system. Shift to appropriate gears early to prevent excessive engine revving, which increases heat output. Maintain steady RPM levels by avoiding abrupt acceleration or deceleration, as these create thermal spikes. Regularly inspect cooling fins and airflow pathways, ensuring they aren’t obstructed by debris or mud. Use appropriate engine oil temperatures by avoiding prolonged idling and giving the bike periodic high RPM runs to facilitate heat dissipation. Implementing these precise controls helps maintain ideal engine temperature, preventing overheating caused by sustained low-speed operation and ensuring reliable performance on slow trails.

Frequently Asked Questions

Can Weather Conditions Affect My Bike’s Overheating Risk?

Yes, weather conditions considerably impact your bike’s overheating risk. High ambient temperatures reduce your cooling system’s efficiency, causing heat buildup in the engine. Humidity can also hinder heat dissipation, while direct sunlight increases surface temperatures. Wind can either help cool your bike by promoting airflow or, in stagnant air, lessen cooling. Always consider these factors and adjust riding or cooling strategies accordingly to prevent overheating during hot, humid, or still conditions.

Are Certain Bike Materials More Prone to Overheating?

Aluminum frames tend to heat up more quickly than steel or carbon fiber due to their higher thermal conductivity. If you ride in hot conditions or under heavy braking, aluminum absorbs and transfers heat faster, increasing overheating risk. Conversely, steel and carbon fiber dissipate heat more efficiently, making them less prone to overheating during slow, prolonged rides. Choosing bike materials based on your riding conditions can mitigate overheating issues effectively.

Does Tire Pressure Influence Bike Temperature During Slow Riding?

Yes, tire pressure affects your bike’s temperature during slow riding. Lower pressure increases tire deformation and flexing, generating more heat via friction and internal deformation. Conversely, higher pressure reduces contact patch and flex, decreasing heat build-up. Properly inflated tires maximize rolling efficiency and minimize heat accumulation, preventing overheating. Regularly check and maintain recommended pressure levels, especially on slow, prolonged rides, to keep your bike cool and performing effectively.

How Does Bike Age Impact Overheating Issues?

As your bike ages, wear and tear on components like the brake system, bearings, and chain increase friction, leading to higher operating temperatures. Over time, lubrication diminishes, causing parts to work harder and generate more heat. Degraded seals or warped rims can also hinder cooling. Regular maintenance, including replacing worn parts and lubrication, helps mitigate overheating risks associated with aging components, ensuring smoother, cooler rides.

Can Aftermarket Parts Cause Increased Heat During Slow Trails?

Yes, aftermarket parts can cause increased heat during slow trails. Studies show that poorly matched components, like high-performance brake pads or oversized rotors, can increase friction and generate excessive heat. For example, improper caliper alignment raises temperature by up to 20%. When you install non-standard parts, verify they’re compatible with your bike’s specifications, as incompatible upgrades can compromise cooling efficiency and lead to overheating during slow, technical riding.

Conclusion

Remember, a well-maintained bike runs cooler and performs better—think of it as a machine, not just a ride. Regular lubrication, attentive maintenance, and adapting your riding style can substantially reduce overheating risks. Monitor signs of excessive heat and adjust your pace accordingly. As the saying goes, “An ounce of prevention is worth a pound of cure.” Staying proactive ensures your bike stays efficient, even on slow, challenging trails, extending its lifespan and your riding enjoyment.