Husqvarna uses 3D printing to improve their tools and equipment by creating lighter, stronger, and more durable parts. This technology speeds up manufacturing, allows quick prototypes, and makes complex designs possible in a single step. It also helps reduce waste and energy consumption, making their products more sustainable. By embracing additive manufacturing, they stay ahead in innovation and quality. Keep exploring to discover how this tech is transforming their industry.

Key Takeaways

- Husqvarna integrates 3D-printed parts to enhance product performance, durability, and customization.

- 3D printing streamlines manufacturing by enabling rapid prototyping and complex geometries.

- The technology supports innovation, quick design testing, and faster market releases.

- It reduces material waste and energy use, contributing to sustainable production practices.

- Husqvarna’s use of 3D printing positions it as an industry leader with advanced, customizable tools.

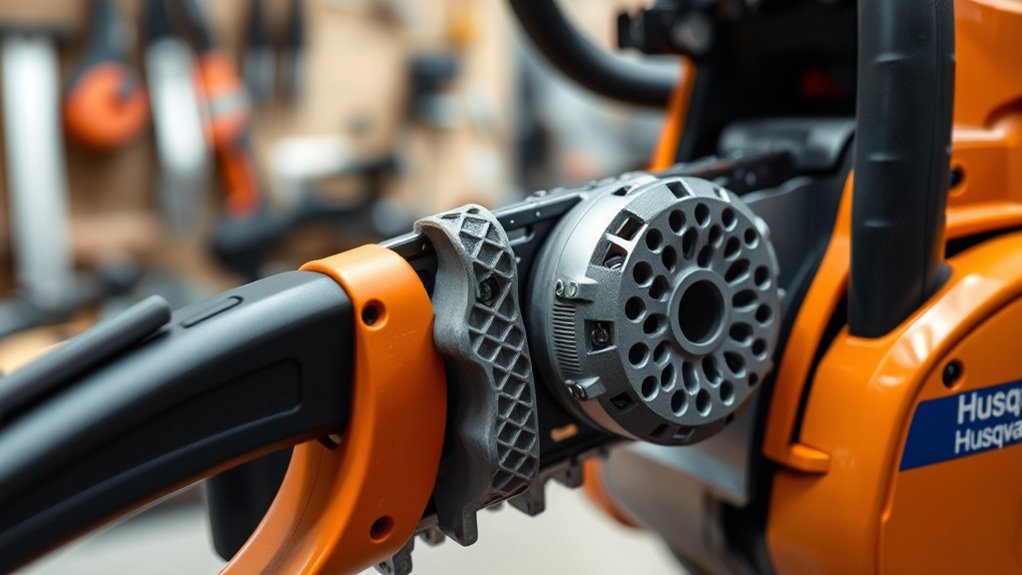

Husqvarna is revolutionizing its manufacturing process by integrating 3D-printed parts into its products. This move allows the company to push the boundaries of material innovation, creating components that were previously difficult or impossible to produce using traditional methods. By adopting 3D printing, Husqvarna can experiment with new materials that are lighter, stronger, and more durable, resulting in products that perform better and last longer. This focus on material innovation doesn’t just enhance product quality—it also opens up exciting possibilities for customization and design flexibility. You’ll notice that parts can be tailored to specific needs without the lengthy lead times typically associated with conventional manufacturing.

Moreover, incorporating 3D-printed parts *considerably* boosts manufacturing efficiency. Traditional manufacturing processes often involve multiple steps, tooling, and lengthy production cycles, which can slow down the overall workflow. With 3D printing, Husqvarna reduces these bottlenecks by enabling rapid prototyping and on-demand production of complex parts. This means you get access to improved products faster, with less waste generated during the manufacturing process. The ability to produce intricate geometries in a single step streamlines workflows, reduces assembly time, and minimizes inventory costs, making the entire process more agile and responsive to market demands.

The use of 3D-printed parts also enhances the company’s capacity to innovate continuously. When you can quickly develop and test new designs, Husqvarna accelerates the cycle from concept to market. This agility allows for more frequent updates and improvements, which benefits you by providing cutting-edge tools and equipment. Additionally, 3D printing reduces the reliance on supply chains for certain components, making the manufacturing process more resilient and adaptable to disruptions. This resilience means you’re less likely to face delays or shortages, ensuring Husqvarna’s products remain reliable and readily available.

Furthermore, leveraging advanced additive manufacturing** helps Husqvarna achieve more sustainable production practices by reducing material waste and energy consumption during manufacturing. In essence, Husqvarna’s integration of 3D-printed parts is a strategic move that combines material innovation with manufacturing efficiency. It’s not just about making products faster; it’s about making them smarter. You get access to tools and equipment that benefit from lightweight construction, complex geometries, and rapid customization—all made possible through advanced additive manufacturing. This approach positions Husqvarna at the forefront of the industry**, setting new standards for innovation, quality, and efficiency that directly benefit you as a customer.

Frequently Asked Questions

How Cost-Effective Is 3D Printing for Husqvarna?

3D printing is quite cost-effective for Husqvarna, as it boosts cost savings by reducing material waste and lowering production costs. It also enhances production flexibility, allowing you to quickly customize parts or produce prototypes without expensive tooling. This agility helps you respond faster to market demands, ultimately saving money and improving efficiency in your manufacturing process.

What Materials Are Used in Husqvarna’s 3d-Printed Parts?

Husqvarna uses advanced material innovations like durable polymers and composites in their 3D-printed parts. They employ cutting-edge printing techniques such as selective laser sintering and fused deposition modeling to guarantee strength and precision. These materials and methods allow Husqvarna to create lightweight, resilient components tailored for demanding outdoor conditions. By leveraging these innovations, they optimize performance, reduce costs, and enhance the overall quality of their products.

How Does 3D Printing Impact Husqvarna’s Production Timeline?

Imagine a fast-moving river, symbolizing Husqvarna’s production flow. 3D printing accelerates your timelines by enabling rapid prototyping, so you can test and refine parts swiftly. It also streamlines inventory management, reducing storage needs and delays. This innovation makes your manufacturing process more flexible, allowing you to adapt quickly to market demands and cut down on lead times, ensuring you stay ahead in the competitive landscape.

Are 3d-Printed Parts as Durable as Traditional Components?

You’ll find that 3D-printed parts can be quite durable, but their material strength varies depending on the filament used. While they’re often suitable for prototypes and certain components, they might not match traditional parts in long-term wear and tear. However, their repair versatility is a big plus—you can quickly produce replacement parts on-site, reducing downtime and making maintenance easier. Overall, they’re a practical option for specific applications.

What Are Husqvarna’s Future Plans for 3D Printing Technology?

Think of Husqvarna as an explorer charting new waters with 3D printing as their vessel. They plan to push future innovations by refining printing techniques and materials, making parts even stronger and lighter. Sustainability initiatives will guide their journey, reducing waste and energy use. You can expect Husqvarna to continue pioneering eco-friendly, customizable tools that revolutionize forestry and gardening, making a positive impact on both industry and environment.

Conclusion

By incorporating 3D-printed parts, Husqvarna boosts innovation and reduces production time. Did you know that 3D printing can cut manufacturing costs by up to 50%? That’s a huge advantage for you as a customer, leading to better, more affordable products. As Husqvarna continues to embrace this technology, expect even more durable and customized equipment. It’s exciting to see how 3D printing transforms the industry and benefits users like you every day.